Know about Backward Curved Centrifugal Fan Specifications from Experts

Constructed of high-quality composite materials, the Symbiosis series of Model UDBC 1 to UBWC 9 are backward curved centrifugal fans designed for handling particulate-free, corrosive or caustic air in high-pressure applications. They are well-suited whereas conventional steel and stainless steel fans are not suitable. Before getting to know about the specifications of Backward Curved Centrifugal Fans, let’s see the basics of ‘Backward Curved Centrifugal Fans’.

About Backward Curved Centrifugal Fans:

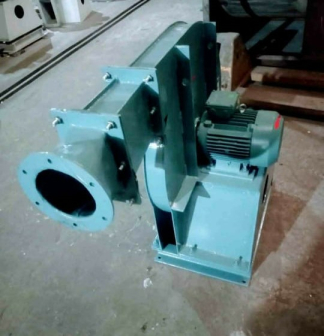

The name, ‘Centrifugal Fan’ is derived from the direction of flow and how the air exits the Fan Impeller radially from the outer circumference of the fan. Backward Curved Fans are also known as ‘Radial Fans’ are Centrifugal Fans with Backward Curved Blades. A Backward Curved Centrifugal Fan is characterized by its cylindrical shape, several large curved blades, and a conical inlet nozzle. These Centrifugal Fans provide very good cooling at high-pressure conditions. The impellers of these industrial fans are highly resistant to dirt & dust.

Backward curved fans are “non-overloading” fans because changes in static pressure do not overload the motor. Its hydraulic efficiency is very high. These External Rotor Motor Fans are ideal for cooling at high-pressure conditions. 9 different series for varying wheel designs allow flexibility in selection. This Design is united for Harsh process requirements and is the most preferred choice for majority of applications.

Backward Curved Impellers made of Steel or Engineering Plastics. The impellers are press fitted on the External Rotor Motor and dynamically Balanced in two planes. Backward Curved Fans can be used with or without scroll Housing, and find its application in sucking operations, and where static required at Fan Inlet is high.

Application of Backward Curved Centrifugal Fan:

Backward Curved Centrifugal Fans can be used with or without scroll Housing, and find its application in sucking operations, and where static required at Fan Inlet is high.

- Backward Curved Centrifugal Fans are used in Low Air Flow and High Pressure Industrial Applications such as -Panel ACs, Air Handling Units, Clean Rooms, Conveying and Drying.

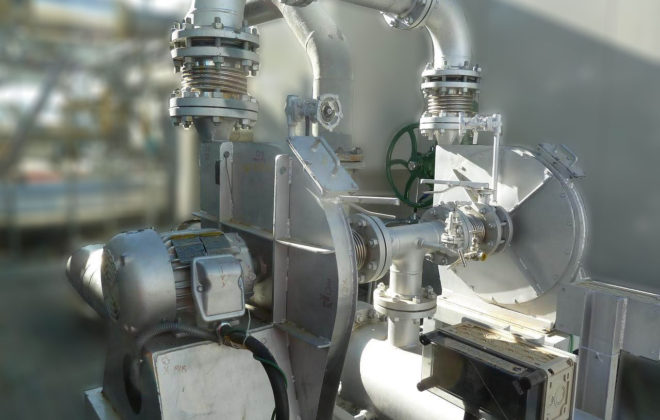

- Our Model UDBC fans are suitable for indoor and outdoor locations in several industries like- fertilizer, metal and mineral processing, marine, Pulp and Paper, petrochemical, pharmaceutical, and water and wastewater treatment etc.

- Typical applications of model UDBC fans include fume-control / fume-exhausting, odor control, oil mist emissions, Pollution/emissions control, process control, high-moisture environments, and scrubbers.

Performance and Design of Backward Curved Centrifugal Fan:

- Air volumes up to 9,50,000CMH

- Static pressures up to 1750 mmWC

- Temperatures up to 550 ℃

- High Peak Total Efficiency up to 82.4%

- Dynamically Balanced as per ISO 1940 – 1 Gr 6.3/Gr 2.5

- Non-overloading power curve.

- Single Width, Single Inlet (SWSI) and Double Width, Double Inlet (DWDI).

- Very high Strength of Impeller with majority of Impellers fully welded for long life and reliability Optimum thickness for low stress.

- Model UDBC fans offer superior air, confirm to all AMCA notified standards and are designed for all AMCA notified Drive and Impeller Support Types.

USHA DIE CASTING INDUSTRIES offers the Backward Curved Centrifugal Fans in multiple sizes, arrangements, construction classes, impeller, and housing widths. Whether standard or custom, each SYMBIOSIS Industrial Fan is designed with unmatched quality and backed by quick service.

However, it is important to select a fan whose performance characteristic meets the required duty point on or near the point of peak efficiency.

USHA DIE CASTING INDUSTRIES (UDCI) is at the forefront of designing premium Backward-Curved Centrifugal Fans to exacting standards and client requirements & expectations. With years of experience and the latest manufacturing facilities, we manufacture these Impellers within close tolerances matching exact blade profiles using mechanized welding procedures.

Contact our Experts to understand the fan requirement for your facility.

Tags In

Related Posts

Recent Posts

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project