SYMBIOSIS Fume Exhaust And Ventilation Systems

SYMBIOSIS FUMES EXHAUST SYSTEMS

SYMBIOSIS offers extensive Fumes Exhaust System Designs to cater to HSE requirements of manpower working in Dusty / Hazardous / Toxic Fumes and Smoke area for Industrial as well as Commercial environments, thereby serving as Air Pollution Control Equipment in Surat.

Fumes exhaust system is installed to confine fumes and other toxic gases / unburnt particles which are generated through various Industrial / Commercial manufacturing – preparation processes.

SYMBIOSIS offers Highly Efficient and Well Engineered systems which are effective and compliant within Pollution control norms.

The System is designed considering the area to be exhausted, number of points of fumes generation, rate of fumes generation, available space for hoods / ducting, locations for ID Fans for complete system extraction or planning for smaller extractions through localized hoods and smaller ID Fans The process is studied and site visits made for proper understanding of HSE requirements / worker issues / recovery requirements etc. A total solution is designed keeping all of the above in mind.

SYMBIOSIS FUMES EXHAUST SYSTEMS Are Sought After In Numerous Industrial

Applications Like:

TEXTILES

Stenter Machine Area Fumes Exhaust

Silk Cloth Industries

Weaving manufacturing Units

Jacquard Manufacturing Units

PAPER MILLS

Laminates Machines Area

Jumbo Paper Making Machine Area

AUTOMOBILE

Pickling, Degreasing And Plating Lines

CERAMICS INDUSTRIES

Furnace Area

DIAMOND INDUSTRIES

Diamond Polishing Machine Area

SUGAR INDUSTRIES

Fugitive Sugar Capture Application

CEMENT INDUSTRIES

Bag Unloading Area And Other Various Processes

RUBBER INDUSTRIES

In Various Processing Applications

UTENSILES / FAUCETS / FITTINGS / BRASS INDUSTRIES

Grinding, Polishing And Buffing Areas

ACID PICKLING APPLICATIONS

In Various Processes In Ferrous And Non Ferrous Mfg

Applications

MINERALS & MINING INDUSTRIES

Loading / Unloading / Transportation applications

WOODWORKING / LAMINATES / PARTICLE BOARD INDUSTRIES

For All Manufacturing Machinery Of Wood Working Applications

PAINTING APPLICATIONS

In All Large And Medium Scale Industries For Hazardous Paint Fumes

Extraction Application

SAW PIPE MANUFACTURING INDUSTRIES

Coating Fumes Extraction Area

SHOT BLASTING / POWDER COATING APPLICATIONS

For Fumes Exhaust From Chamber

FOOD INDUSTRIES

In Various Processing Applications

SYMBIOSIS Fumes Exhaust System For Medium To Large Scale Metal Industries

SYMBIOSIS is Reputed in Design / Manufacture / Supply / Commissioning of complete Fumes Exhaust System for Fumes generated in Metal ( Ferrous / Non Ferrous) Melting in Induction Furnaces / Argon Oxygen Decarburizing ( AOD ) Furnaces / Electric Arc Furnaces ( EAF ) / Cupola Furnaces in the Metals Industry.

Direct Fumes Suction from and near the Furnace as well as Residual Fumes Extraction from Furnace Shed Area is provided by way of specially designed Suctions Hoods / Extractors, High Efficiency designed Ducting Systems, Air Pollution Control Systems ( Bag House ), High Performance Centrifugal ID Fans, Electrical Panels, Chimney etc..

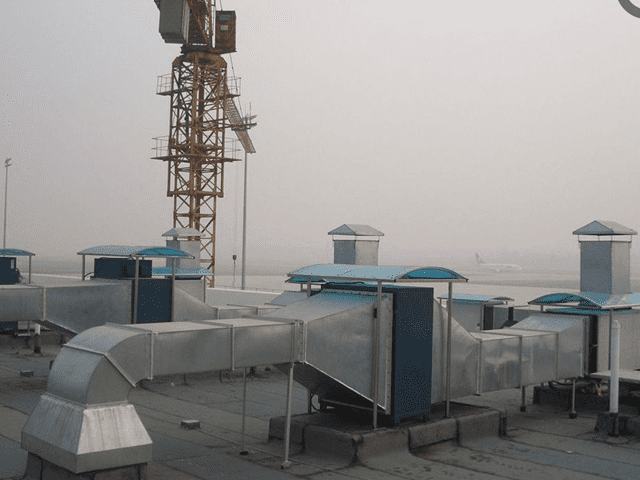

SYMBIOSIS KITCHEN VENTILATION SYSTEMS

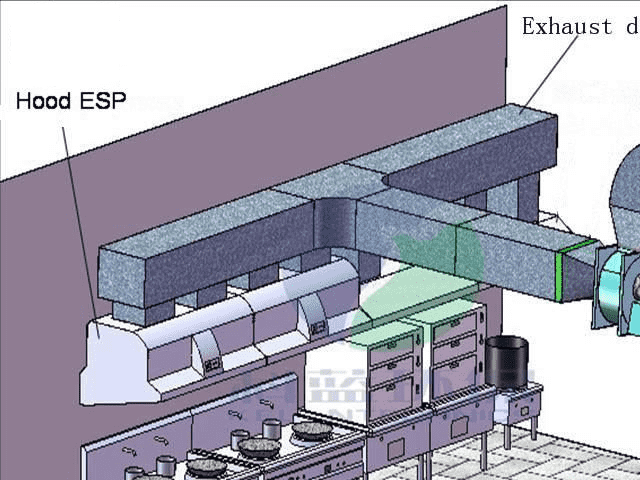

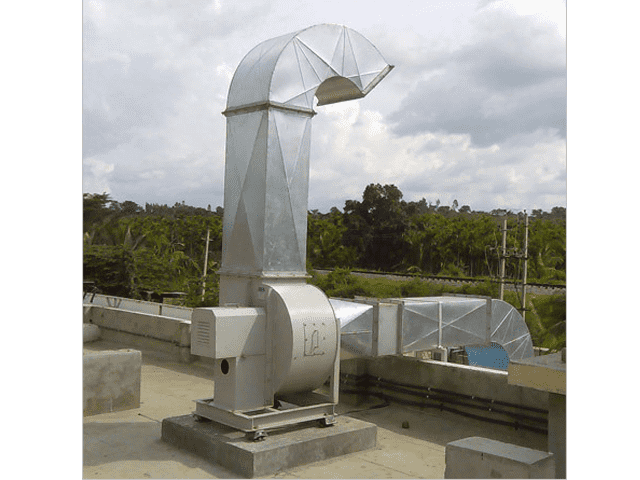

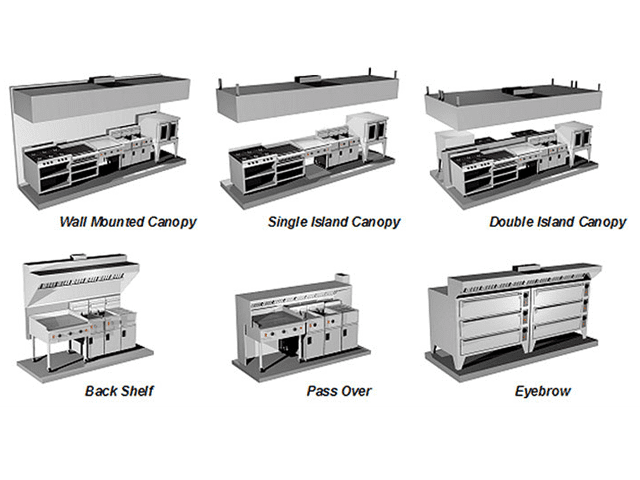

SYMBIOSIS Kitchen Ventilation Systems specializes in the treatment of air from kitchens. Kitchen Ventilation presents the problems of grease, smoke and odour not usually found in other ventilation systems. SYMBIOSIS Equipment used in Kitchen Ventilation uses an Extractor Hood or Canopy and a Filtering system. The fan for the ventilation system may be located within the kitchen / in the duct system nearby and also if required far away from the kitchen as per site conditions.

SYMBIOSIS KITCHEN VENTILATION DESIGN

Construction of SYMBIOSIS Axial Flow Fans

The main factors considered by SYMBIOSIS when designing a Kitchen Ventilation system are:

- Workload of the kitchen

- Amount, type and power of cooking equipment used

- Layout and shape of the kitchen

- Number of staff working in the kitchen

- The need for easy cleaning and maintenance

- Energy efficiency