How are industrial fans & blowers important for the cement industry?

The cement industry

is one of the largest and the most fundamental industries throughout the world, because of the material, mixtures, and binders it creates. Some of the industries like engineering, transportation, road construction, public highways and works, and even private institutions are highly dependent on the cement industry. Thus the cement industry is vital to the progression of society and the betterment of the public’s lives.

The cement industry is a highly energy-intensive industry, in which the correct airflow systems are crucial to maximizing production and profitability. In the cement manufacturing plant, a lot of collecting, sifting, mixing, binding, pouring, and molding processes are done every day, in multiple batches simultaneously. So naturally, heavy-duty equipment is needed to quicken, facilitate, and simplify these tasks as well as provide safety & security to the industry’s workers. This is why several high-quality fans are one of the first pieces of equipment the cement industry actively seeks out.

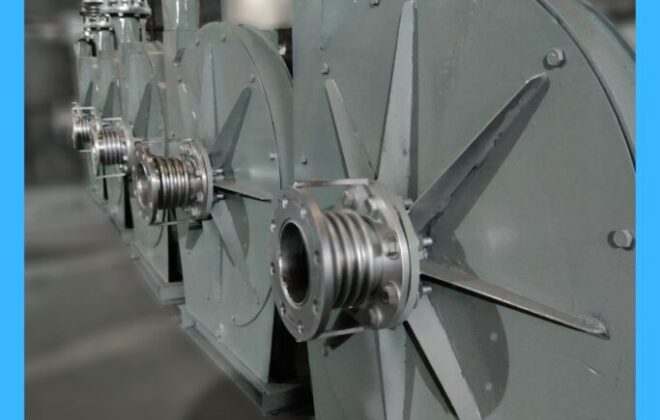

Industrial fans play a vital role in cement manufacturing, as they are utilized at almost every stage of cement production. Based on the purpose, industrial fans of various types are used in different steps of cement manufacturing. However, the heavy-duty fans used are usually built to perform two main and basic jobs: to supply a gust of air, or to remove any exhaust, toxic gases, or material in the air.

Let us see how important industrial fans and blowers are for the cement industry.

- Maintaining the health & safety of cement plant and its workers: It is important to note for the cement industry that through its multi-step cement manufacturing processes lots of byproducts are emitted. It includes solid, liquid, fumes and even toxic gas wastes, because of the materials it handles daily. Most of it is dust and material particles that are found in the air, which the workers breathe and that pollute the air. Such air pollution is very harmful to the workers’ respiratory health, especially if exposed to it regularly. Industrial Fans–especially the exhaust and ventilation types–help filter the air while preventing the air pollution. Thus it is not only advantageous to the workers’ health and safety, but the environment as well.

- Providing comfortable working environment through proper ventilation: Industrial fans and blowers are also useful for providing a comfortable, temperature-standard working environment that makes the cement production work more bearable. Proper installation and maintenance of these fans will enhance comfort, productivity and efficiency within the cement manufacturing facility.

- For Material handling in cement manufacturing: Cement is one of the most important products in the modern world. It is manufactured by making use of raw material like lime stone, clay, and marl. These raw materials are processed in several steps to produce cement. Industrial process fans find their application in the cement manufacturing process at various steps like – material handling, grinding, preheating, cooling, etc. The cement and asphalt industry also needs specialized types of fans to move materials from one station to another, as well as heavy-duty fans to finely grind and crush tough materials ready for mixing, and to preheat all kinds of mixtures at certain temperatures, with a specific amount of pressure.

- Raw Materials such as limestone, clay and sand are collected from the quarry. Large-sized rocks of these raw-materials are crushed at the quarry. Once the raw materials are crushed into gravels, they are proportioned in the manufacturing plant. During this crushing and proportioning of raw-materials, industrial fans are used for material handling and dust exhaust.

- Induced draft fans are a must to enable the heating process in the kiln. Such fans favor the gas flow and the combustion of the fuel by providing sufficient air.

- Coal mill fans provide air for burning coal and eliminate the exhaust gases after the coal is burnt in the rotatory kiln.

- Cooling fans are used to blow cool air and bring down the temperature of the clinkers during the clinker process in the cement manufacturing. Once the clinkers are cooled, they are crushed to a fine powder which is considered as the cement.

- Exhaust fans/Dedusting fans are used to dedust the plant and also exhaust the unnecessary gases.

- Maintaining the Energy efficiency: Being a high energy-intensive industry, ‘energy efficiency’ plays a key role in the cement industry. Industrial fans, as high energy consumers, can result inhigh energy costs. They are an important cost factor in the cement production process. So if these fans are designed energy-efficiently, they can present a huge opportunity in terms of lowering the overall energy consumption of the whole plant (especially when variable-speed drives are used). A customized fan design, adapted to cater specific process requirements can lower the energy consumption, while reducing the energy costs.

- To produce the first class cement, the industrial fans at the cement plant must be designed to avoid imbalance caused by different reasons. A well thought-out design of industrial fans and blowers helps the cement plant operators to lessen shutdown periods, reduce energy costs and ensure a safe and reliable production; which is vital for the cement production process.

Usha Die Cast Industries has been serving the cement industry for over two decades. It is well versed with the cement industry’s special requirements regarding efficiency, availability and performance of process fans. Its SYMBIOSIS brand centrifugal fans and blowers are used throughout the cement production process. Contact us to avail high quality fans which work at precise operating conditions like high temperature and pressures.

Related Posts

Recent Posts

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project