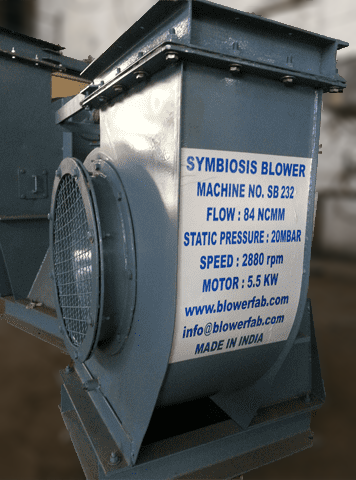

SYMBIOSIS CENTRIFUGAL BLOWER AND FANS

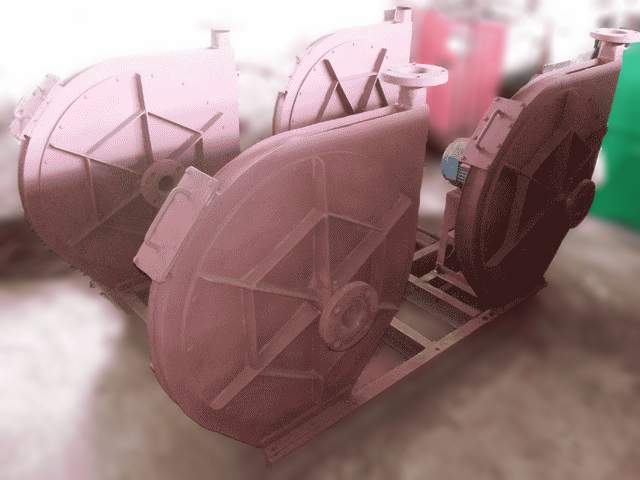

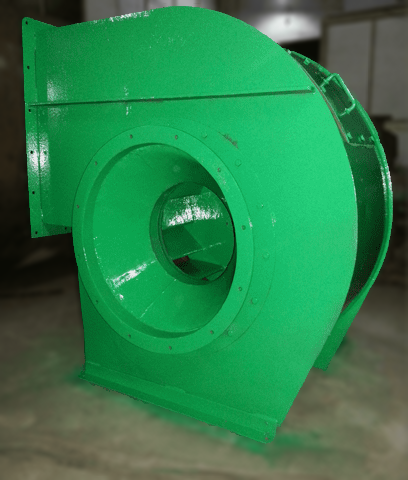

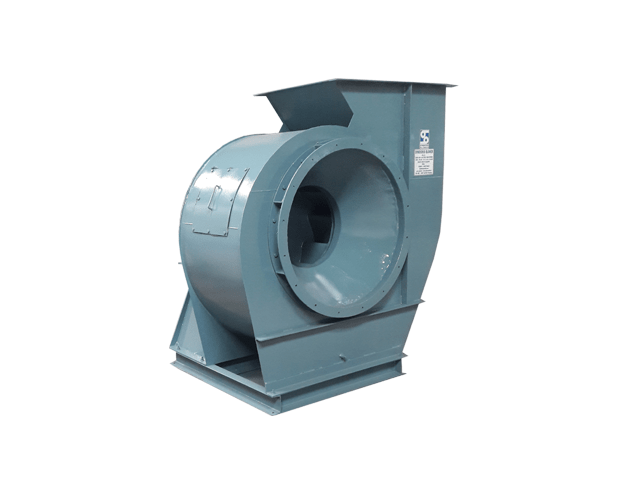

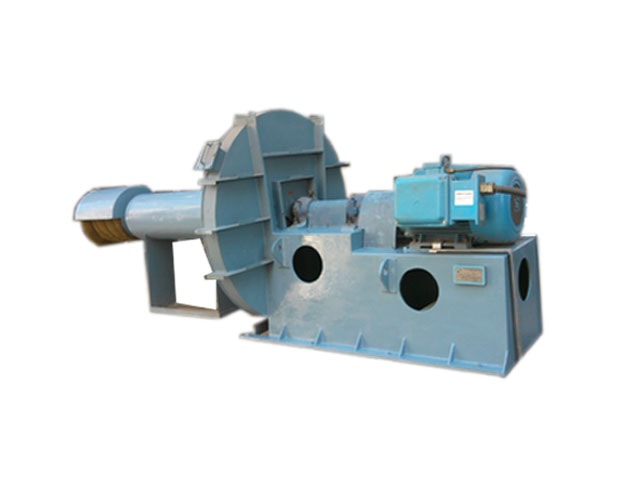

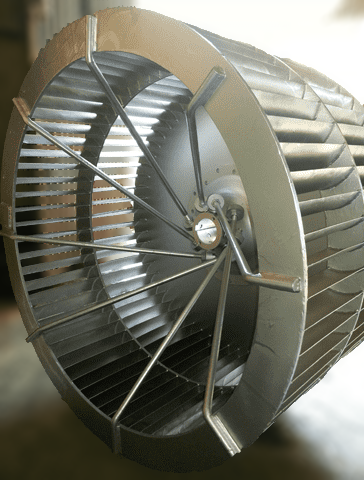

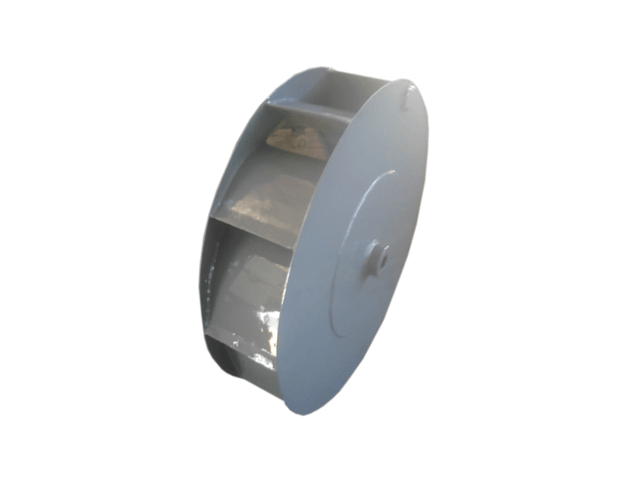

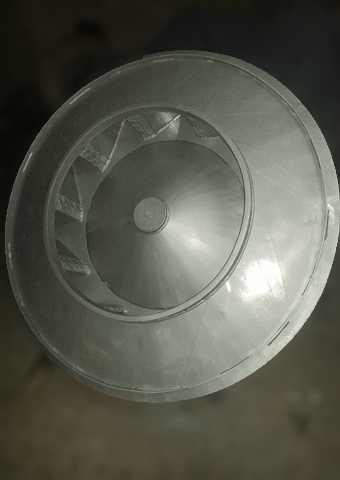

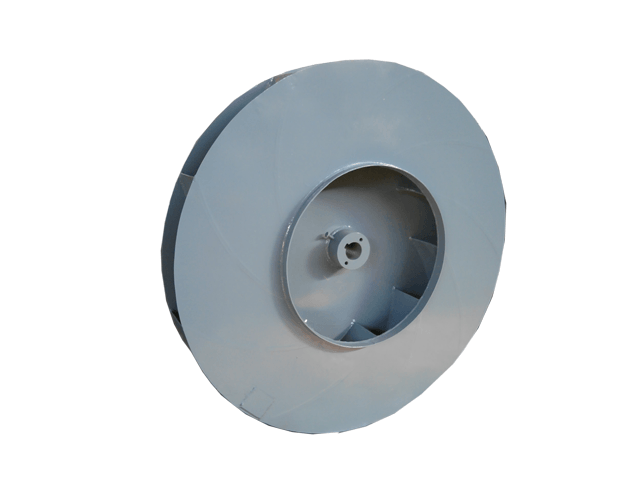

Usha Die Casting Industries is a Leading Centrifugal Blower Fan Manufacturer in India. A revolving impeller is used by a centrifugal blower fan to draw in air or gas and release it radially. By generating centrifugal force, it causes the air or gas to flow from the impeller’s periphery to the Centre. Since 1999, we have produced premium centrifugal blowers and fans under the SYMBIOSIS brand, in all significant aerodynamic designs, featuring:

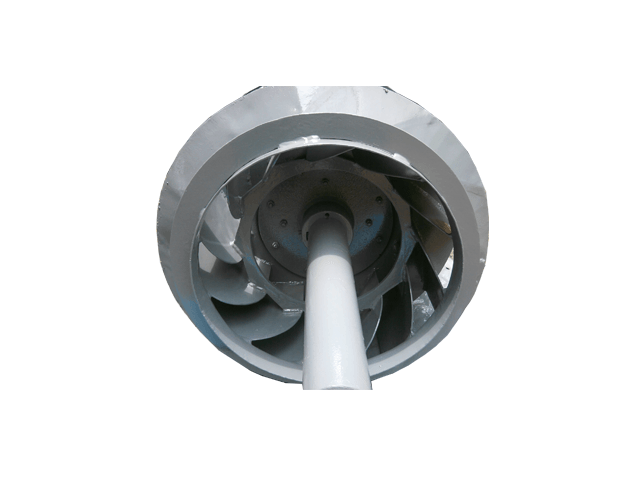

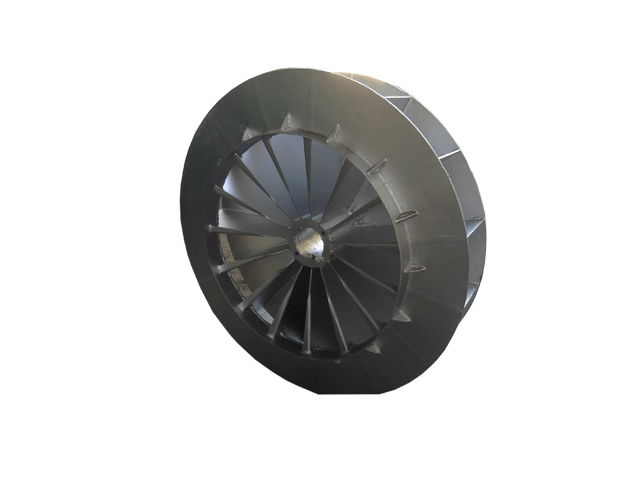

Backward Curved Aerofoil Type

Backward Curved Blower

Backward Inclined Type

Radial Bladed Type

Direct Drive Centrifugal Fans

Coupling Driven Type SYMBIOSIS Blower

V Belt Driven Type SYMBIOSIS Blowers

Special Construction SYMBIOSIS Blowers

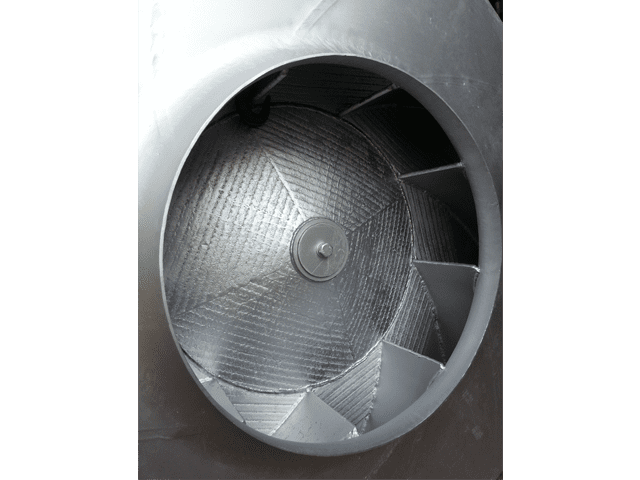

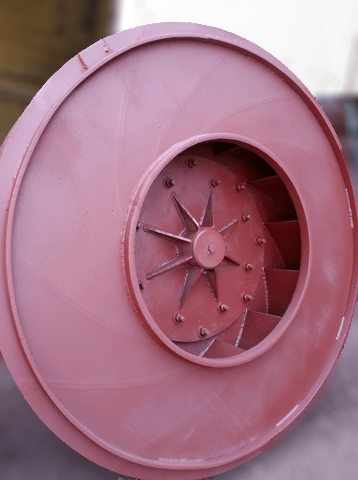

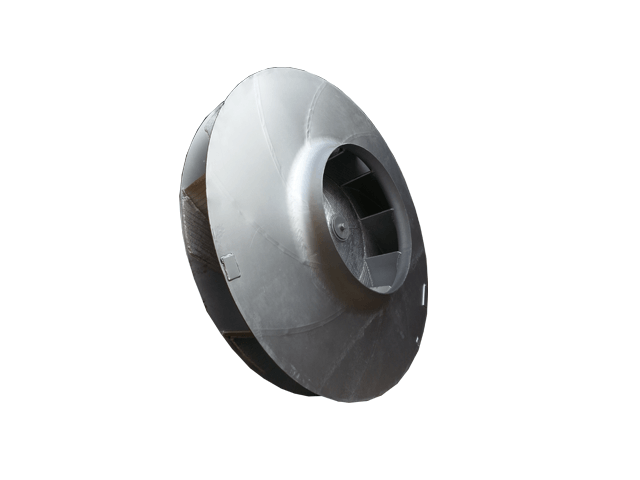

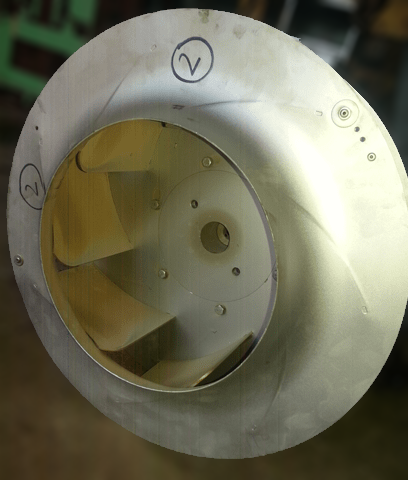

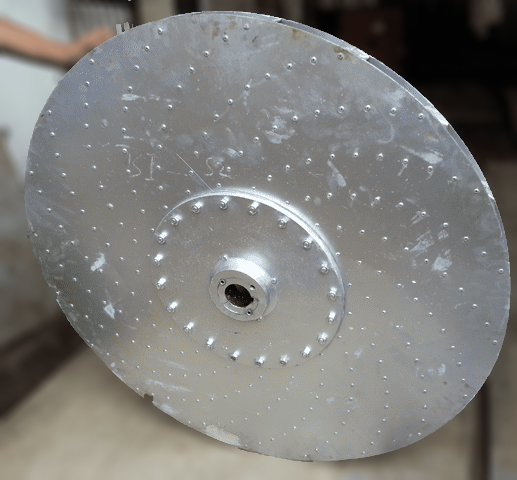

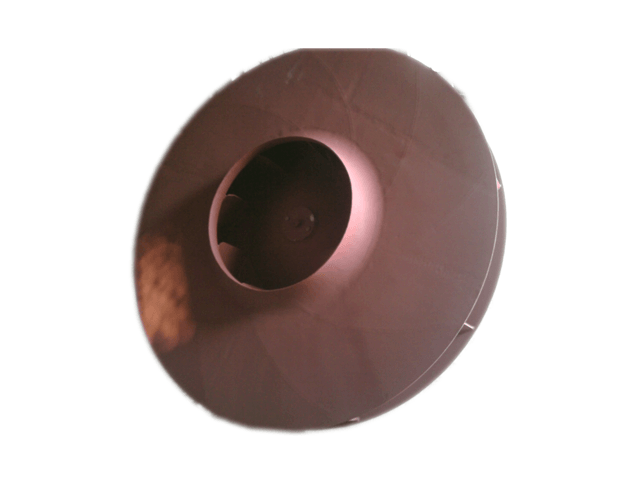

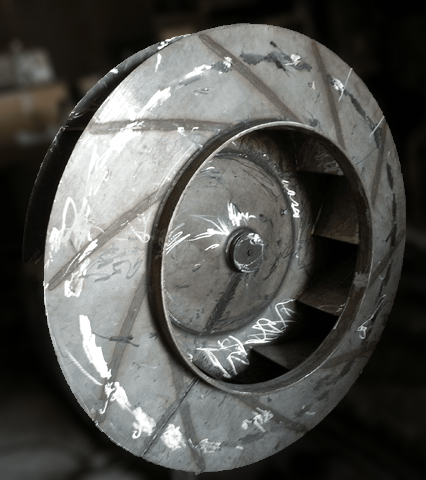

Impeller For Centrifugal Fans

In order to analyze the performance and make ongoing improvements to SYMBIOSIS Centrifugal Blowers, we have also established a facility for centrifugal blower test setup.

High-pressure air blowers, high volume low-pressure air blowers, and fans with a maximum capacity can all be designed and manufactured by us.

- Flow : 9,50,000 M3/Hr

- Static Pressure : 2000 Mmwc

- Inlet Temperature : 550 DegC

WE OFFER INDUSTRIAL FANS AND BLOWERS

Drive Arrangement

Inlet Box Positions for Centrifugal Fans

Designations of rotation & discharge of centrifugal fans

Motor Positions for Belt Drive Centrifugal Fans

Class 1 ( Lightest Construction suitable only for Low Speeds )

Class2

Class3

Class4

Class5 ( Heaviest method of Construction for High Speed )

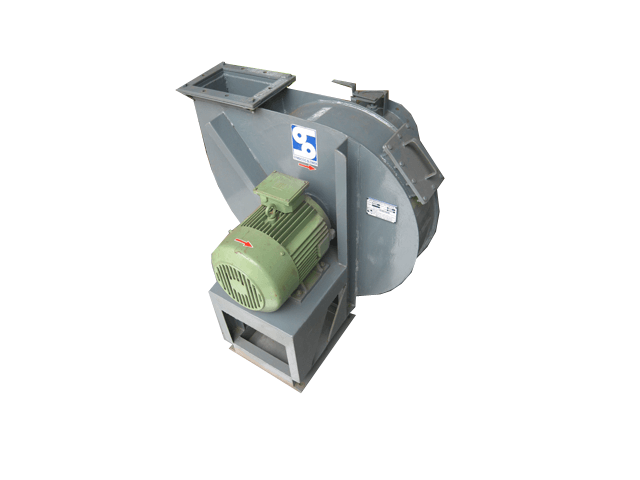

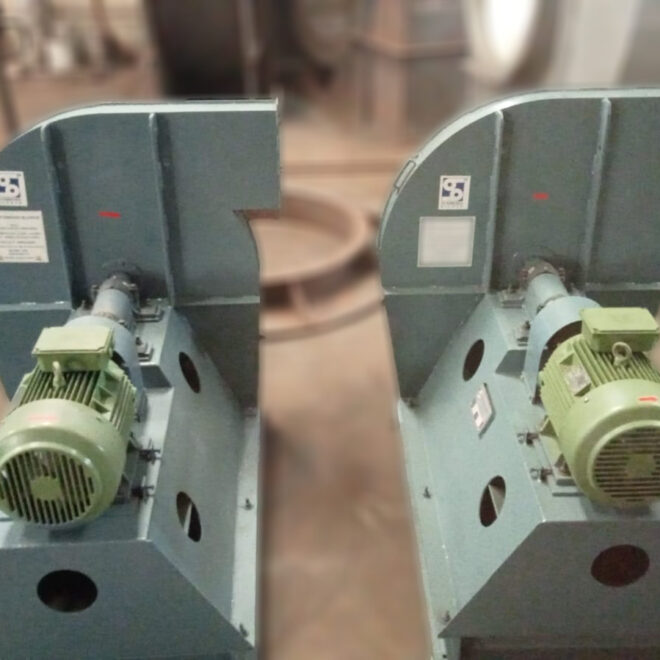

Direct Driven Type

V Belt Driven Type

Direct Coupling Driven through Shaft

Cantilever Impeller Arrangements

Simply Supported Type Impeller Mounting

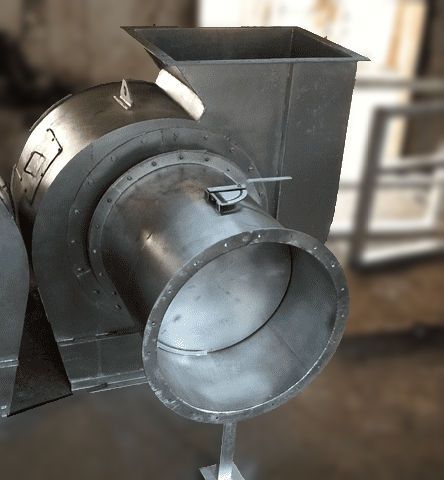

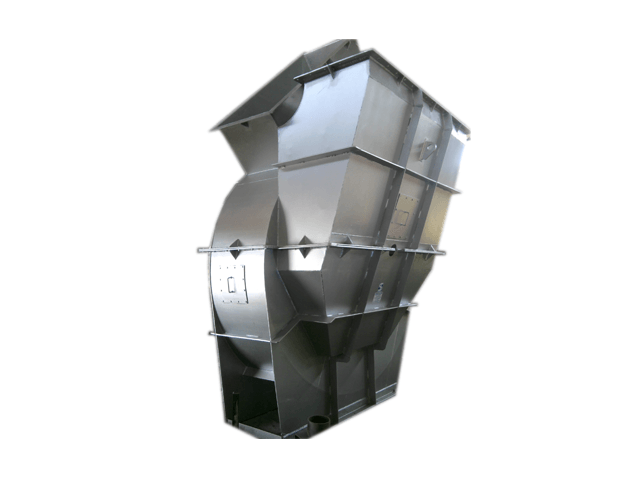

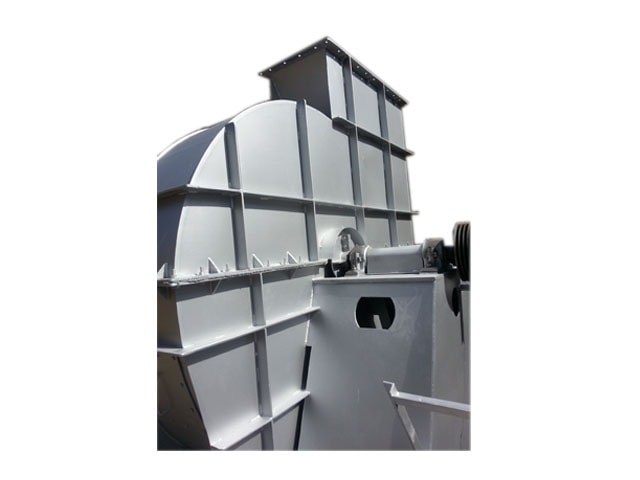

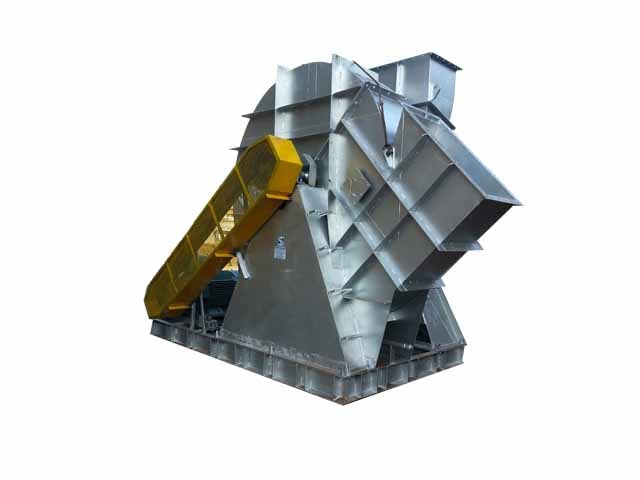

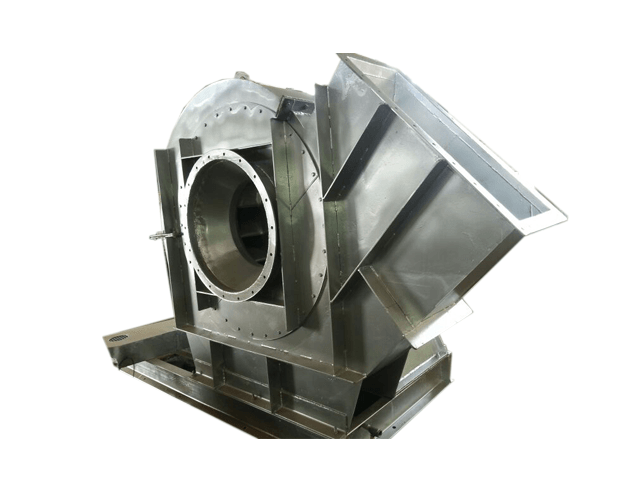

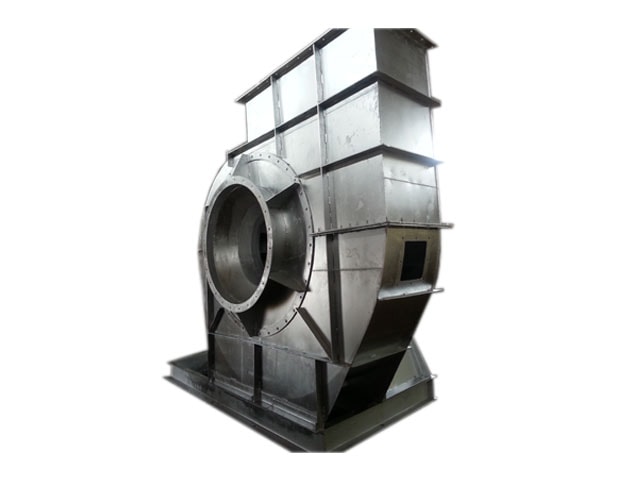

KEY CONSTRUCTION FEATURES OF SYMBIOSIS BLOWERS

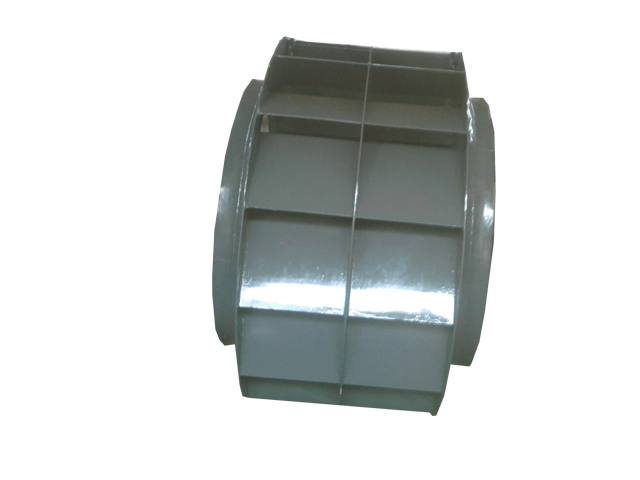

- Casting Thickness of Heavy Gauge Construction with adequate Flat Stiffeners all around resulting in Rigid Structural Design for Casing which Guarantees performance in Harsh environments & conditions

- Continuously welded housings offer strongest possible construction.

- Impeller construction is optimized based on proven Engineering calculations and analysis. High Strength materials selected for high stress applications with experience to provide Impeller Hub Design in Welded / Flanges & Bolted / Taper Lock Arrangement / Parallel Bore / Taper Machined Bore types.

- Shaft Machining done between Centers and Tolerances maintained as per ISO Std.

- Bearing selected based on Speed, Type of Drive, Operational Loads, Temperature, Application and customer inputs if required for maximum life and trouble free operation. Bearing Locators & Reference fit-up points provided in all Fans for future maintenance requirements.

- Motors selected based on starting method and with adequate margin over and above operating duty point. Efficiency Levels Offered as per customer requirements. Motor Alignment System with Pads, Shims, Bolts provided for all Indirect driven Fans.

- Casing to Shaft Entry point sealing provided for Process fans .

- Taper Lock Pulleys of reputed Brands provided for ease in maintenance and inventory. Couplings selected depending on the type of loads, torque requirement, maintenance setup at customer site.

- Extended Insulated Plug Construction designed for very high temperature fans upto 500 Deg C

- Impeller / Wheel Statically Balanced & finally Dynamic Balanced on CNC Machines as per ISO 1940-1

- Number of Accessory options available for variety of customer applications. Guards, Covers, Heat Sinks, Dampers, Metallic & Flexible Bellows / Connectors, Drains, Inspection Spouts, Gaskets, Monitoring instrumentation, Bird Screens, Louver's, Inlet Filters, Drains, Anti Vibration Mounts, Matching Flanges, Application specific painting, Abrasion resistant construction etc.

- Detailed Operation & Maintenance Manual provided along with TESTED OK Report of Factory QA Dept for Constructional & Performance Testing ( wherever applicable) .Impregnable / Plastic Wrap with appropriate Wooden Box, Pipe Frame packaging provided for National / International Cargo.

- We Offer complete range of Centrifugal Fan / Blower Sizes & Impeller Designs which allow us to meet all Industrial Air Movement requirements. Our Success is based on our Engineering, Experience, Broad Product range, Quality Assurance & Guaranteed After sale Service & Technical support.

SYMBIOSIS BLOWER ACCESSORIES OPTIONS

- Matching Flanges

- Inlet or Outlet Dampers - Parallel Blade or Opposed Blade

- Variable Inlet Vanes (Viv's) to Control Fan Performance

- Guide Vanes and Flow Straighteners

- Silencers or Noise Attenuators

- Inlet Filters for Dusty Environment

- Inlet Boxes to Replace Inlet Elbows in Tight Situations

- Shaft Seals - Types: Friction, Double Lip, Mechanical, Stuffing Box, Stuffing Box With Gas Purge, Contact less

- Cooling Fins in Cast Aluminium for Heat Dissipation

- Actuators and Positioners - Pneumatic or Electrical

- Flexible Connections - to Reduce Vibration Transmission

- Inlet And Outlet Transitions

- Anti-Vibration Mounts - Spring or Rubber-In-Shear

- Safety Mesh Guards for Open Inlet or Outlet

- Lagged or Cladded Casings for Noise / Heat Reduction

- Bearing & Condition Monitoring Equipment

- Split Casings to Facilitate Transport, Impeller & Shaft Removal

- Anti-Sparking and Explosion Proof Construction

- Outlet Evase' to Reduce Velocity for Static Regain

- Variable Speed Control to Vary Fan Performance

- Wear Liners/Plates, Hard Facing or Thermal Lining for Abrasive Conditions

- Bearing & Condition Monitoring Equipment

- Backward Withdrawal for Easy Access to Impeller

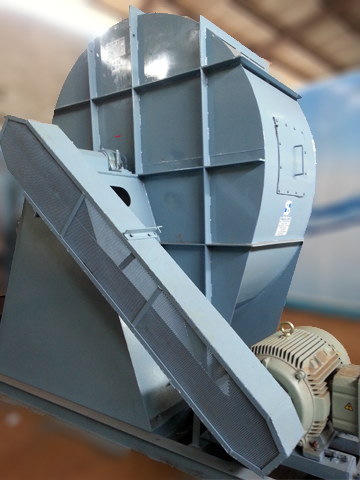

HIGH PRESSURE CENTRIFUGAL FAN WITH BACKWARD CURVED BLADES FOR PHARMACEUTICAL INDUSTRIES

2600 CFM

48 INCHWC

20 DEG C

2880 RPM

DIRECT DRIVE

37 KW

PHARMACEUTICAL APPLICATION

DB AS PER ISO 1940 – GR6.3

MEDIUM PRESSURE CENTRIFUGAL FAN WITH BACKWARD CURVED BLADES AND TAPER LOCK BUSH

1400 CMH

500 MMWC

20 DEG C

2880RPM

DIRECT DRIVE

TAPER LOCK BUSH AT IMPELLER TO SHAFT JOINT

3.7 KW

AGRICULTURAL DRYING APPLICATION

DB AS PER ISO 1940 – GR6.3

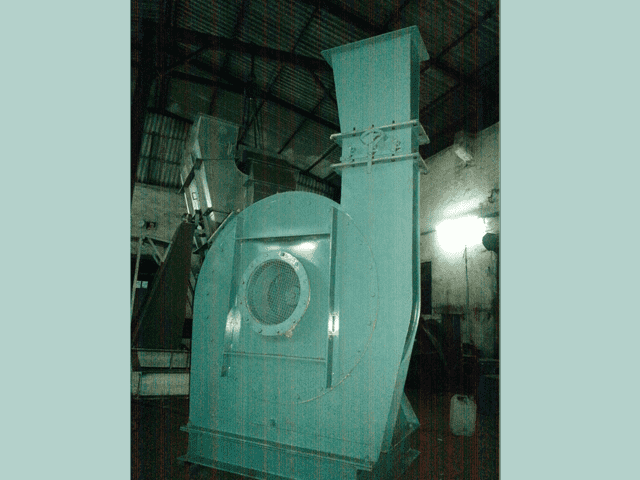

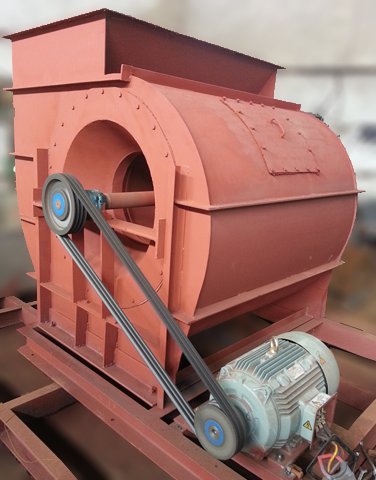

MEDIUM PRESSURE CENTRIFUGAL ID FAN WITH BACKWARD INCLINED BLADES FOR COAL FIRED BOILER USED IN TEXTILE DYEING MILLS

13000 CMH

450 MMWC

180 DEG C

1460 RPM

V BELT DRIVE

37 KW

DB AS PER ISO 1940 – GR6.3