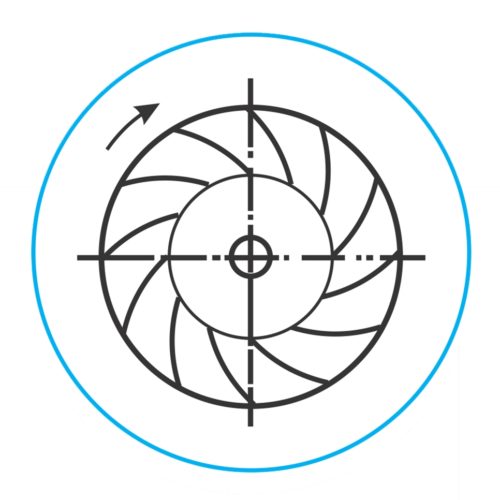

Backward Curved Blower

The single Thickness Backward Curved Impeller is highly Efficient and only slightly less Efficient than its Aerofoil Counterpart. It has ideal Aerodynamic characteristics with maximum Design efficiency upto 82.4 %. It can be used for clean air or medium concentrations for medium to high pressure industrial applications. 9 different series for varying wheel designs allow flexibility in selection. This Design is united for Harsh process requirements and is the most preferred choice for majority of applications.

SYMBIOSIS MOST POPULAR MODELS FOR BACKWARD CURVED BLOWER

With years of application oriented experience and latest Manufacturing facilities, we manufacture these Impellers within close tolerences matching exact blade profiles using mechanized welding procedures.

With welding distortion Management, maintaining minimal impeller run out before dynamic balancing and with special handling of Impeller, SYMBIOSIS delivers world class fans and blowers for your Critical applications

Our Blowers are truly SYMBIOTIC to your process. Think of Air…… Think of SYMBIOSIS Blower.

We offer the Backward Curved Centrifugal fan in multiple sizes, arrangements, construction classes, impeller and housing widths. Whether standard or custom, each SYMBIOSIS Industrial Fan is designed and built with unmatched quality and backed by responsive service

BACKWARD CURVED FAN PERFORMANCE & DESIGN

- Air volumes up to 9,50,000CMH

- Static pressures up to 1750 mmWC

- Temperatures up to 550 ℃

- High Peak Total Efficiency up to 82.4%

- Dynamically Balanced as per ISO 1940 - 1 Gr 6.3/Gr 2.5

- Non-overloading power curve.

- Single Width, Single Inlet (SWSI) and Double Width, Double Inlet (DWDI).

- Very high Strength of Impeller with majority of Impellers fully welded for long life and reliability Optimum thickness for low stress.

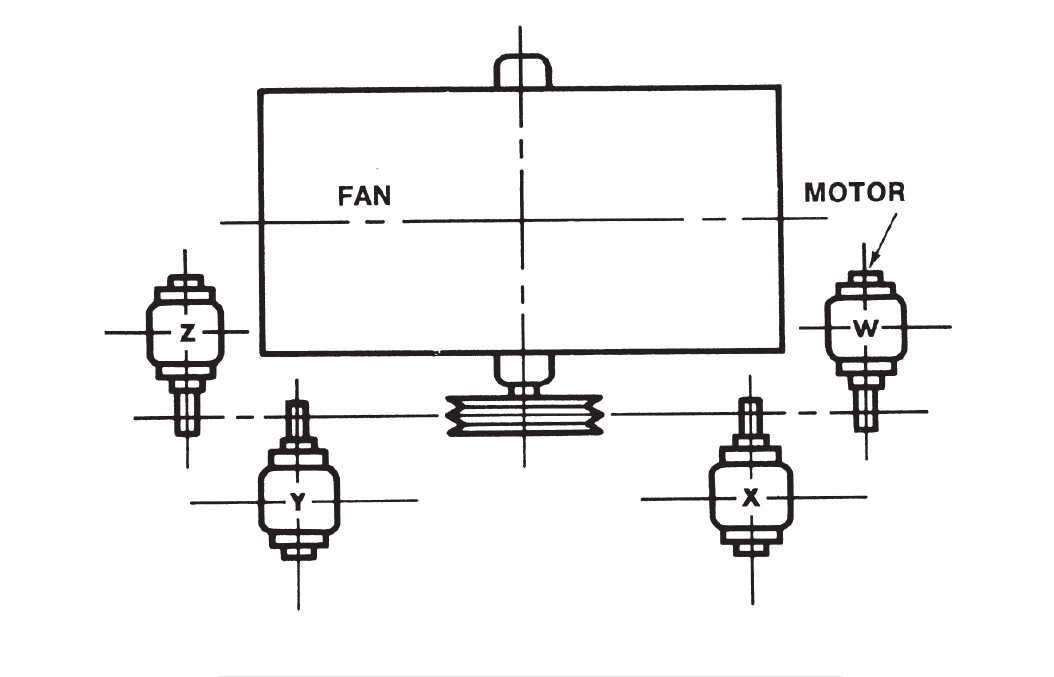

Arrangement of Drive

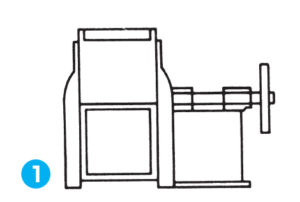

ARRANGEMENT NO. 1 SWSI

Wheel overhung. Bearing in bracket supported by fan housing. For beit drive or direct connection.

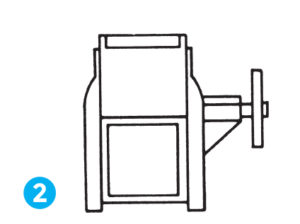

ARRANGEMENT NO. 2 SWSI

For belt drive or direct connection. Wheel overhung. Bearing in bracket supported by fan housing

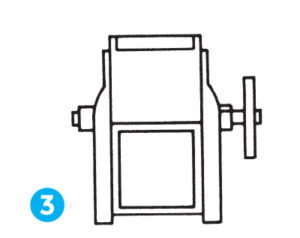

ARRANGEMENT NO.3 SWSI AND DWDI

For belt drive or direct connection. One bearing on each side and supported by fan housing.

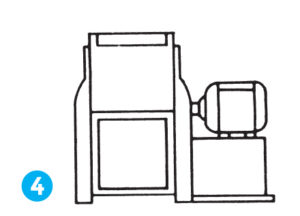

ARRANGEMENT NO. 4 SWSI

For direct drive. Wheel overhung on motor shaft. No bearing on fan. Base mounted or an integrally direct connected motor.

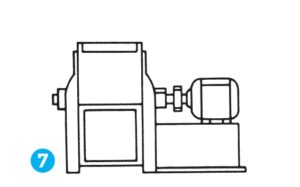

ARRANGEMENT NO.7 SWSI AND DWDI

For belt drive or direct connection. Arrangement No.3 plus base for motor.

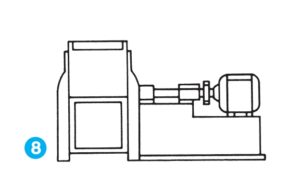

ARRANGEMENT NO.8 SWSI

For belt drive or direct connection. Arrangement No.1 plus base for motor.

ARRANGMENT NO.9 SWSI

For belt drive Arrangement No.1 designed for mounting prime mover on side of base.

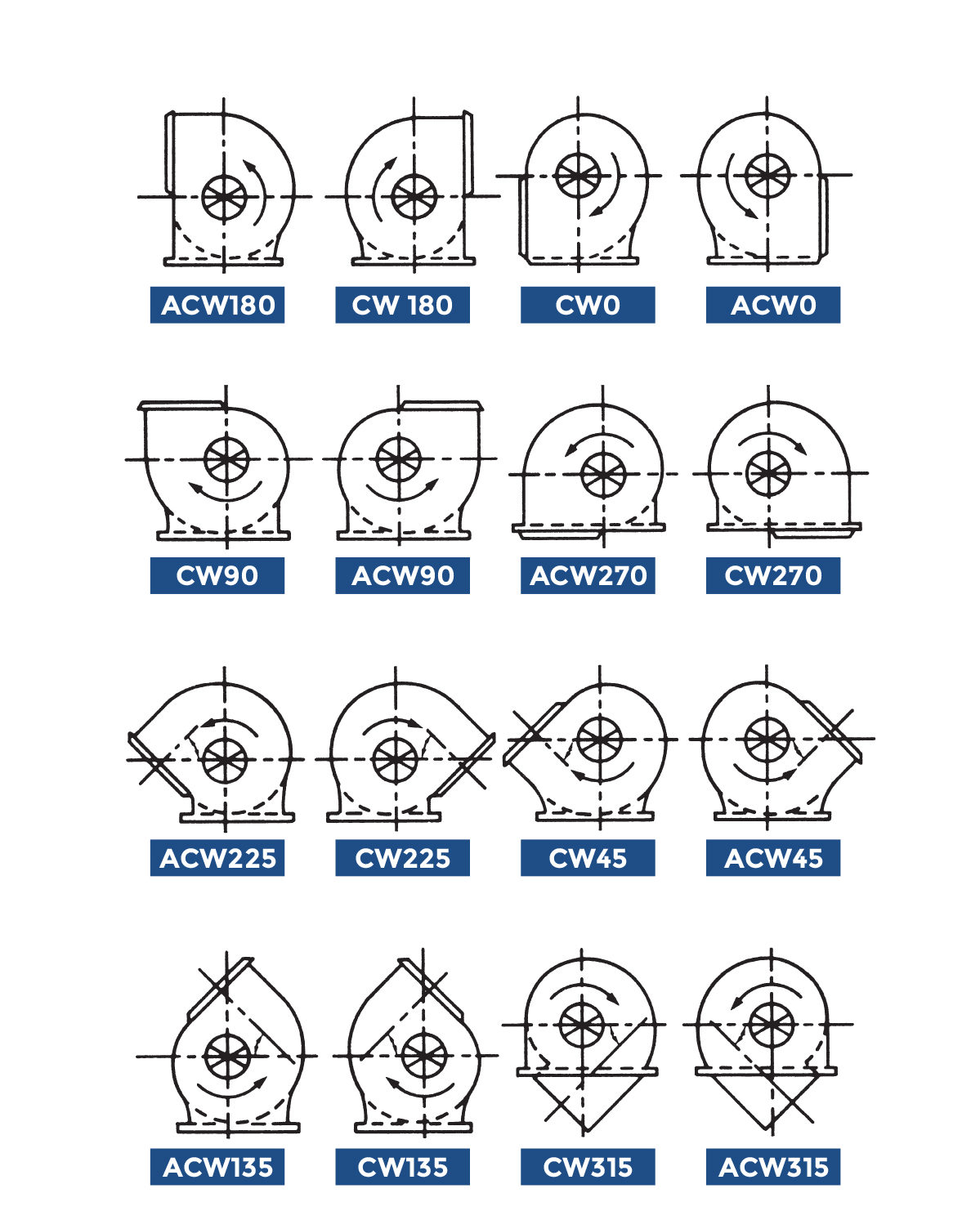

Direction of Rotation And Discharge

Standard Motor Position