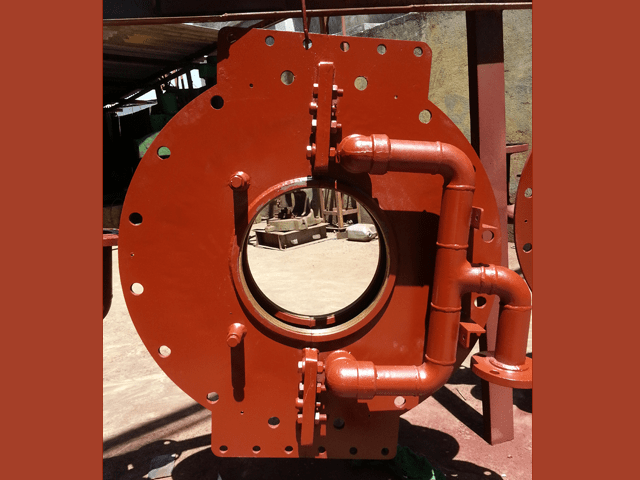

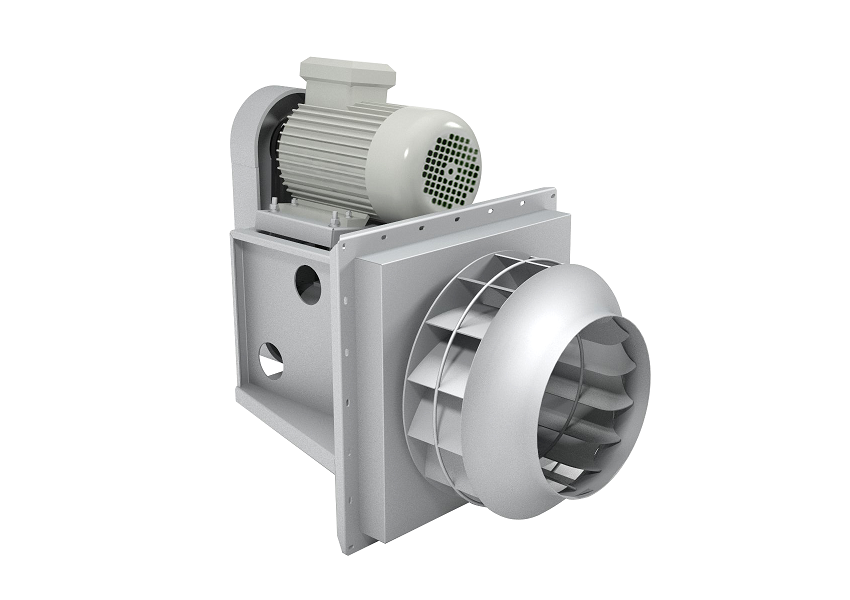

How to Identify Problems Causing Industrial Fan Failure?

Industrial fans operating in various ventilation systems play a key role in the production process of many industries. Therefore it’s important to know how to identify problems causing Industrial Fan failure to maintain and monitor them. One of the most common ways to carry out continuous or periodic condition monitoring of industrial fans is to check the malfunctions and their symptoms.

As an experienced Industrial Fans manufacturer in India, Usha Die Casting Industries has listed the following typical signs indicating fan problems. One must check these points before opting for a fan replacement.

Noise:

If the industrial fan makes an unusual noise, it is evident to have incurred some damage. Excessive noise or squeaking noise from the fan can be caused by the following reasons.-

- An impeller hitting the inlet or housing

- The loose shaft or bearing

- Problems with the belt drive

- Inadequate lubrication

- Misaligned seals

- Foreign material

- Fretting corrosion between the inner race and the shaft

Airflow:

Inadequate airflow can also be a culprit for an industrial fan failure. It is caused by-

- Improper blade angle setting

- an impeller not centered with inlet collars

- Backwards installed or running impeller

- Missing cut-off

- Dirty or clogged inlet

- Slow fan speed

- Improper running clearance or

- Improper inlet cone-to-wheel fit

Not enough airflow to the duct system indicates the actual system is more resistant to airflow than expected. Other probable causes of inadequate airflow are closed dampers or registers, loose insulating duct liners,s or leaks in the supply ducts.

Movement:

If the fan is not moving at all, then also it indicates a mechanical or electrical problem in the fan. The main reasons for such signs are-

- Blown fuses

- Loose pulleys

- Broken belts

- Incorrect voltage and/or excessive line drop or inadequate wire size,

- seized bearing

- A load inertia that is excessive for the motor.

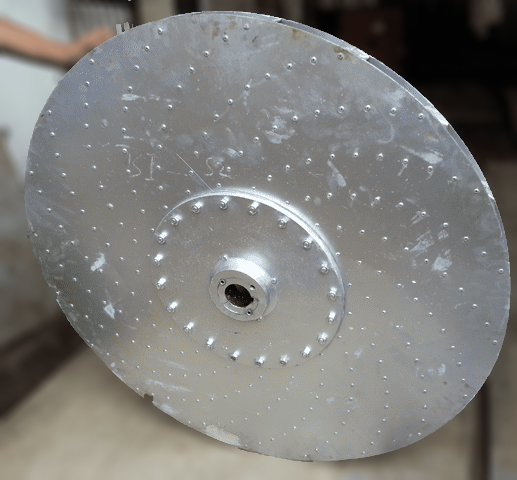

Vibration:

Excessive fan vibration is another indication of fan breakdown, which is caused by-

- Impeller imbalance,

- Motor and sheaves being improperly balancing of motor and sheaves

Along with that also make sure to check that-

- Key lengths are correct

- Fan shaft seals are rubbing and

- Motor has the right bearings

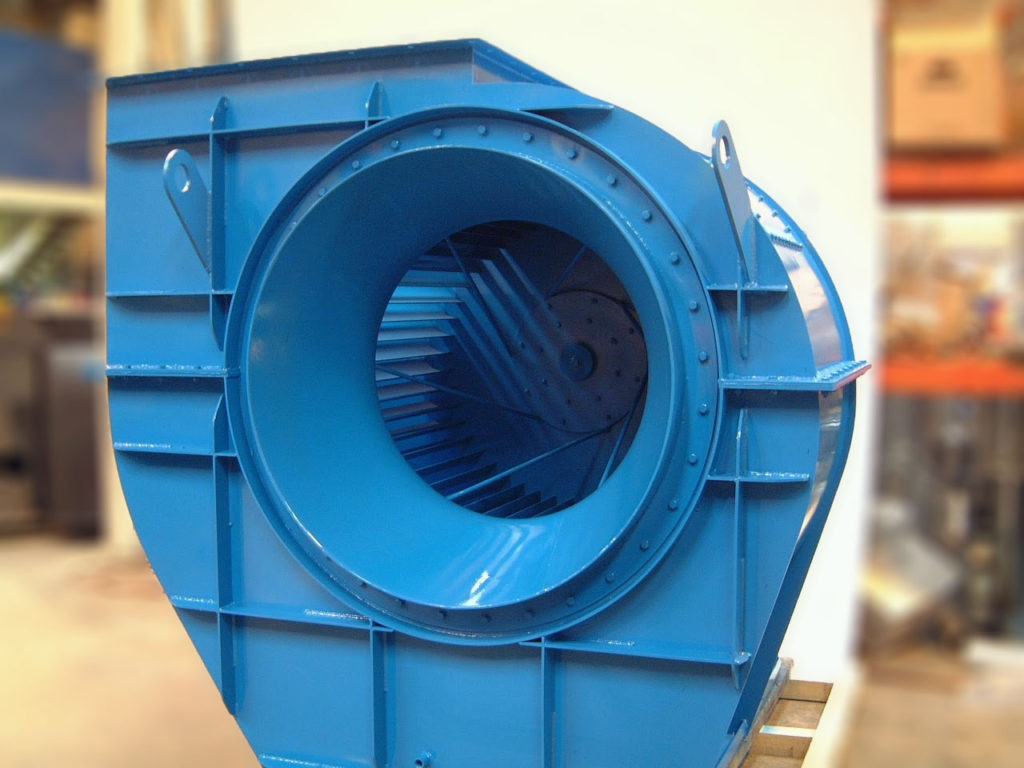

Complete Fan Failure:

Higher trending vibration and rapidly increasing bearing temperatures indicate bearing ring failure, leading to complete fan failure. Other reasons include failing belt drive or coupling, shaft failure, an Impeller Failure due to abrasive or corrosive wear.

Knowing the reason for fan failure from the above checklist and making required repairs correctly in the first place will ultimately save your cost of replacing an industrial fan.

However, if you experience any critical functioning issue with your industrial fan, our fan experts can assist you to assess the exact situation and supply the right replacement fan suitable to your needs.

Get in touch with Symbiosis Blowerfab to know more detail about the Industrial/Centrifugal Blower fan.

Related Posts

Recent Posts

- How Industrial Fans Transform Ventilation Systems in Smart Factories

- How Centrifugal Blowers Help Optimize HVAC Systems in Large Facilities

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency