4 Important Factors to Look for Before Buying Industrial Fans from India?

Industrial blower fans are used in industrial units to blow huge volumes of air. Industrial fans are commonly used for ventilation, drying, cooling, removal of dust, exhaust cleaning, etc. They find their application in several industries like paper , textile , cement , glass , transportation, vehicular exhaust applications, HVAC, and so on. Fans generate pressure to move air against a resistance caused by ducts, dampers, or other components in a fan system. The fan rotor receives energy from a rotating shaft and transmits it to the air.

Types of Industrial Fans

Ask any reputed Industrial Fans manufacturer in India , he will suggest different types of industrial fans for several industrial processes. Depending on the industrial applications(Put suitable link here), fans can be divided into two parts. They are Centrifugal Fans and Axial Fans .

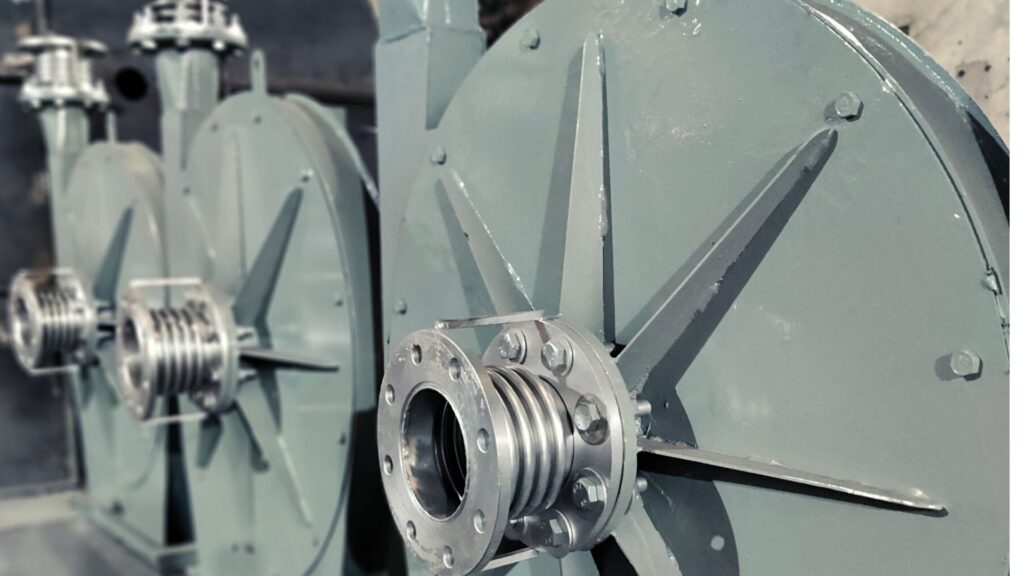

1). Centrifugal Fans –

Centrifugal fans feature revolving impellers and employ centrifugal force to blast air or gas. The fans have a revolving disc that rotates the blades to create centrifugal force. The wheels in centrifugal fans suck in air and steer it in the appropriate direction. Once a wheel has drawn in the air inside the cage, it is expelled at 90 degrees by the blades and propelled out. The air is radially forced forth by the impeller, then tangentially pushed away from the blades by the impeller. The pace with which the air is blown out rises as it nears the finish, causing pressure to grow. The centrifugal fans are best suited for high-pressure applications.

2). Axial Fans –

The blades of axial fans extend radially outward. The air travels in the same direction as the fan wheel’s spinning axis. With the aid of the blades, the air is spun off from the center point to the perimeter. When the fan blades push air out, they produce aerodynamic pressure. DC Axial blowers are better appropriate for low-pressure applications due to their small design. Axial fans work well for small-scale exhaust applications (put the )with a certain amount of air, dirt, and smoke.

Things to Look for Before Buying Centrifugal Fans from India?

Before investing in an Industrial Fan, it is very crucial to understand the mechanism that will provide the highest efficiency. As a trusted industrial fans manufacturer in India, we suggest 5 incredible ways to boost efficiency in an industrial blower fan. These are the steps one must look for before purchasing a fan from an industrial blower fan seller in India.

1). Fan Design:

The most critical factor in choosing the right fan type and size is determining the exact airflow and needed outlet pressure. The amount of air required is dictated by the process requirements, which are usually defined by heat transfer rates or the amount of combustion air or flue gas to be handled.

It is frequently more difficult to calculate or forecast the system pressure demand. Pressure drop over the length of the ducting system, bends, contractions and expansions in the ducting system, pressure drop across filters, drop-in branch lines, and other factors should all be investigated thoroughly. These pressure dips should be applied to any fixed pressures required by the process

2). Safety Panel:

The fan’s efficiency is also influenced by the safety margin chosen. The safety margin must be determined based on conversations with the process equipment provider in all circumstances where the fan demand is connected to the process/other equipment. In general, a safety margin of 5% over the maximum flow rate required can be used.

3). Fan Installation:

The fan’s installation and mechanical maintenance are also important factors in the fan’s efficiency. For the impeller’s efficient operation, the following clearances (typical values) should be maintained.

• Axial overlap –5 to 10 mm for 1 meter plus dia impeller

• Radial clearance –1 to 2 mm for 1 meter plus dia impeller

• Backplate clearance –20 to 30 mm for 1 meter plus dia impeller

• Labyrinth seal clearance –0.5 to 1.5 mm

4). Resistance of the System:

System resistance plays a significant role in determining a fan’s performance and efficiency. The resistance of the system varies based on the procedure. The creation of coatings/degradation of the lining in the ducts, for example, alters the system resistance somewhat. In other circumstances, duct changes substantially move the operating point, resulting in poorer efficiency. In such circumstances, the fan must be replaced to retain the same level of efficiency as previously.

As a result, the system resistance must be evaluated regularly, especially when changes are made, and appropriate action is done for the fan to operate efficiently.

Industrial blower fans play a vital role in temperature and pollution control industrial processes. As a trusted industrial fan manufacturer in India, we can assist you with your needs.

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry