Comparison between the Fan, Blowers, and Compressors Made Easy

Fan Blowers Compressors are widely used across various industries for ventilation and industrial process requirements. Since they are ideal for handling complex processes, they have become essential for different applications. Hence understanding the parameters and specifications of Fan Blowers Compressors are prerequisites for their right selection.

While the Fan Blowers Compressors generate a pressure increase in gas and have a corresponding flow capacity; fan blowers compressors are differentiated by the method used to move the air, and by the system pressure, they must operate against.

In this blog, we’ll explore the differences between Fan-Blowers-Compressors through their characteristics and application-specific factors.

Functioning/Operation of Fan Blowers Compressors:

Fan:

A mechanical or electro-mechanical device is used to create airflow, to provide and accommodate a large flow of air or gas to various parts of a building or other structures. Fans generate pressure to move air (or gases) against a resistance caused by ducts, dampers, or other components in a fan system. A fan moves large amounts of gas with a low increase in pressure, by rotating a number of blades, connected to a hub and shaft. It is driven by a motor or turbine.

Blower:

The term ‘Blower’ is often used interchangeably with a fan. However, the blowers can achieve much higher pressures than fans. It is the equipment used for moving gas with a moderate increase of pressure, as a more powerful fan. A fan in the blower rotates and vacuums the air in the suction section. The trapped air is then pushed into the outlet side. By changing the angle of the blades, a blower will be able to push air in any direction you want it. SYMBIOSIS Centrifugal Blowers offer the most reliable service for your application areas in terms of size, performance, and technology.

Compressors:

Compressors are mechanical devices used to increase pressure in a variety of compressible fluids, or gases, the most common of these being air. Compressors pressurize air or gas usually through mechanical means like pistons.

Pressure Ratio :

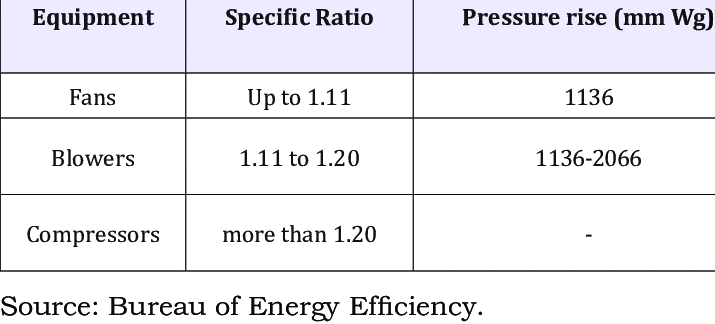

An air compressor operates at high pressure to volume ratio, while an air blower operates at a low-pressure ratio. As per the American Society of Mechanical Engineers (ASME) the specific ratio (i.e. the ratio of the discharge pressure over the suction pressure) is used for defining the fans, blowers, and compressors. See the table below.

Application of Fan Blowers Compressors:

- The fans are mostly used in the sectors of air conditioning,

- Blowers are used in situations, where the system resistance is higher than that for a fan. Blowers are also used to produce negative pressures for industrial vacuum systems.

- Major types are centrifugal blower and positive-displacement blower. A forced hot air furnace that needs to move air throughout a house. Another example is a hairdryer, or blow dryer, which must overcome somewhat higher system losses than a basic fan (specifically the heating element and the nozzle that is used to accelerate the flow to a higher velocity). Centrifugal blowers are generally used for combustion air supplies, cooling and drying systems, fluid bed aerators, air conveyor systems, dust control, etc. The Positive displacement blowers are also used in pneumatic conveying, and for sewage aeration, filter flushing, and gas boosting, as well as for moving gases of all kinds in the petrochemical industries.

- Compressors are used across the industries to provide shop or instrument air; to power air tools, paint sprayers, and abrasive blast equipment; to phase shift refrigerants for air conditioning and refrigeration; to propel gas through pipelines; etc. Compressors find applications in different industries. Some of the common applications and industries that utilize compressors include the following:

- Medical and Dental applications

- Oil & Gas applications

- Truck and vehicle-mounted compressors

- Laboratory and specialty gas compression

- Food and beverage processing applications

At UDCI, we have a wide range of high-efficiency industrial fans & blowers as well as air compressors, (Fan Blowers Compressors) that can be used for a wide range of applications.

Contact our expert to find out which is more suitable for your industry.

Tags In

Recent Posts

- How Industrial Fans Transform Ventilation Systems in Smart Factories

- How Centrifugal Blowers Help Optimize HVAC Systems in Large Facilities

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency