What Cement Manufacturers Should Expect From the Industrial Fan Components?

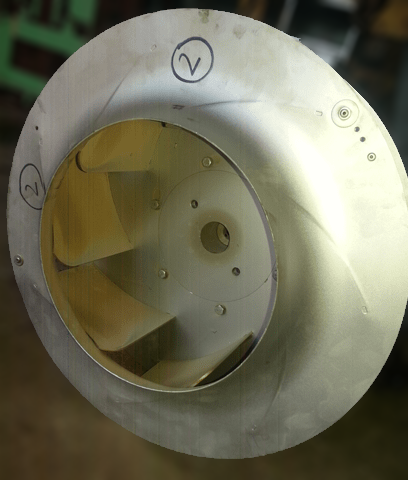

Fans play a key role in the cement manufacturing processes by recirculating air, ventilating hazardous gases, and cooling clinker. That means it’s worth careful consideration and close collaboration with professionals like Usha Die Casting Industries to ensure you’re making the optimal components for your system. Here are a few key things cement manufacturers should ensure they get from the fans that power their ventilation and air pollution control system.

Well thought out Design for Stability andse of Installation for cement industry

Don’t just think about the fan/blower. Think about everything that goes into an efficient, effective ventilation system. A well-designed industrial fan/blower helps the cement plant operators to lessen shutdown periods, reduce energy costs and ensure safe and reliable production. Everything you need to know about the fan’s features, finishes, storage, installation, and safe operation of your unit should be in the manual.

Want to know more about ‘How to select the right industrial fan?’

Testing for Low Vibration and Temperature

High vibration in a fan can break down lubricants in the bearings and, additionally may cause metal fatigue in the bearings. Excessive vibration can cause fasteners to loosen or can cause fatigue failure of structurally loaded components. Know about the potential sources of vibrations from the ‘vibration experts’ working with the fan manufacturer Look for a thorough trim balancing testing process, sound quality assurance, and a careful monitoring system to ensure safe operations and the longest possible life for the fan and bearings.

Efficiency to Conserve Energy and Cost

The cement industry is the most energy-intensive industry of all, wherein the energy-efficiently designed industrial fans are essential for lowering the overall energy consumption of the whole plant. The right industrial fan in the cement manufacturing facility can drive tremendous efficiency, satisfying increasing energy consciousness as well as providing cost savings. opt for the fan options, which reward you with reduced power use, reduced maintenance costs, improved operation, and reliability. Check for additional energy efficiency measures, if any, which are specific to fans and compressed air systems.

Service and Maintenance

While proper routine maintenance of fan & fan components is essential, proper maintenance actually starts during design. With the right planning and preparation, you can minimize or even avoid problems in fan components. Our service and maintenance activities are carried out by experienced fan specialists, who ensure you get optimal equipment availability and uninterrupted production.

As and when you do need fan maintenance help, contact us and we’ll be there for you.

It’s important to work with a fan manufacturer who can meet the specifications of the cement manufacturing process with high efficiency, high quality, and impeccable reliability. With its rich experience, Usha Die Casting Industries (UDCI) has been consistent in all these spheres. Through our ongoing research process, great design options, and rigorous quality assurance, we realize the optimal solution for every case of application.

Looking for industrial fans for your Cement Manufacturing facility? If yes, then contact us to avail high-quality fans.

Recent Posts

- How Industrial Fans Transform Ventilation Systems in Smart Factories

- How Centrifugal Blowers Help Optimize HVAC Systems in Large Facilities

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency