What are Zero-Leakage Centrifugal Fans | 4 Industries they are Widely Used In

Zero-leakage centrifugal fans/Industrial blowers and fans installed in large commercial buildings have thousands of field assembled joints. The joints connect the duct sections and duct-mounted accessories like access doors, fire/smoke dampers, etc. The ducts increase the chances of leakage in blower fans and their accessories.

Leakage reduces the amount of air delivered, wastes energy, and ultimately money. It is necessary for industry owners to opt for zero leakage fans. Water and other fluid leaks are easily detectable. But, air leaks remain undetected on simple observation. The heating, ventilation, and air conditioning (HVAC) industries have developed several standards to minimize leakage. How to measure the leakage is yet to be formulated.

Fans that are over-sized for their service requirements do not operate at their best efficiency points. In severe cases, these fans may operate in an unstable manner because of the point of operation on the fan airflow-pressure curve. Over-sized fans generate excess flow energy, resulting in high airflow noise and increased stress on the fan and the system. Consequently, over-sized fans not only cost more to purchase and to operate, they create avoidable system performance problems. The use of a “systems approach” in the fan selection process will typically yield a quieter, more efficient, and more reliable system.

Zero-Leakage Centrifugal Fans Required in Industries:

Gas-tight and zero-leakage centrifugal fans are needed for the containment of hazardous organic & inorganic compounds in industrial plants.

Zero leakage and gas-tight centrifugal blowers can be used in the following industries:

1. Zero-Leakage Centrifugal Fans for Pollution Control Industry:

Due to mishandling, natural hazard, or technical glitches, 30 million tonnes of natural gas is wasted in leakages. The leakages can be avoided to a major extent when the fans applied are gas-tight. Your industrial air pollution control requirements will vary based on local regulations, air stream composition, and size/scale of the operation All of these variables will influence your air pollution control solution and process fan specifications.

2. Zero-Leakage Centrifugal Fans for Printing & Ink Industries:

The extensive processing of printing and ink industries generates volatile organic compounds and air pollutants. These organic compounds evaporate during the production process. If the waste gases are not handled properly, they leak into the environment causing photochemical reactions. Organic materials combined with pollutants, cause ground-level ozone emissions in the atmosphere.

Zero leakage fans are of absolute necessity in the printing and ink industries.

3. Zero-Leakage Centrifugal Fans for Petroleum Industry:

About 30% of gas is leaked in the petroleum industry. The leaks can be due to several reasons. For examples loose tubing connections, piping connections, air traps, leaky regulators, and obviously a faulty and leaky blower fan.

Petroleum industries can save on money as well as on environmental hazards with gas-tight and zero-leakage centrifugal fans from a trusted centrifugal blower fan manufacturer in India.

4. Zero-Leakage Fans for Chemical Industry:

Hydrogen Sulfide gas is the main source of sulfur. A high concentration of H2S gas can be lethal. In oil refining and other chemical processes, it must be removed. The H2S gas is removed and sulfur is extracted.

The sulfur extraction process needs a high temperature, high pressure, and zero-leakage centrifugal fan to handle the toxic gases.

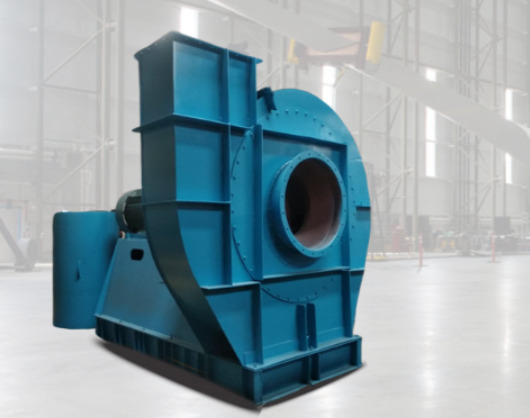

As a trusted zero-leakage centrifugal air blower manufacturer in India, we provide high-quality blower fans to several industries. The centrifugal fans are specially constructed to minimize leakage of toxic gases in the air stream.

Blowerfab is a trusted industrial and blower fans manufacturer in India. We have several years of experience in constructing zero-leakage centrifugal fans and blowers to ensure no waste occurs in production.

Tags In

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry