Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

Dust, fumes, extreme temperatures – the ceramic industry is a demanding landscape for efficient ventilation.

The ceramic industry is a broad and diverse sector that encompasses the manufacture of a wide range of products using ceramic materials. These materials are typically made from clay, earthen elements and powders, which are shaped and then fired at high temperatures to create a hard, brittle, and heat-resistant material.

From bustling studios crafting exquisite pottery to large-scale factories producing tiles and sanitaryware, efficient airflow is crucial. But navigating this complex landscape requires more than just any off-the-shelf solution.

Ventilation Challenges Faced in Ceramic Industry-

The ceramic industry faces several ventilation challenges due to the nature of its processes. Here are some of the key problems:

Dust:

- Generation: Grinding, cutting, polishing, and other processes generate large amounts of fine dust, posing health risks to workers and impacting equipment performance.

- Explosion hazard: Some ceramic dusts are combustible, creating a potential explosion hazard if not properly controlled.

- Settlement: Dust can settle on equipment and surfaces, hindering production efficiency and product quality.

Fumes:

- Glazing and firing processes: Release harmful fumes containing volatile organic compounds (VOCs) and other chemicals, impacting air quality and worker health.

- Odour: Certain processes can generate unpleasant odours that can be uncomfortable for workers.

Temperature and Humidity:

- High temperatures: Firing kilns and other equipment generate significant heat, requiring adequate ventilation to maintain a comfortable and safe work environment.

- Humidity control: Some ceramic processes require specific humidity levels, making humidity control crucial for product quality and production efficiency.

Airflow and pressure:

- Draft and stagnation: Poor airflow can lead to drafts, stagnant air pockets, and uneven temperature distribution, impacting worker comfort and productivity.

- Pressure imbalances: Improper ventilation systems can create pressure imbalances that can affect dust control and air quality.

Solutions for Maintaining Proper Air Ventilation in Ceramic Industry

To tackle these problems, Symbiosis Blowerfab steps in with some effective and reliable industrial air ventilation systems, that offer high-efficiency ventilation, specifically designed for the ceramic industry.

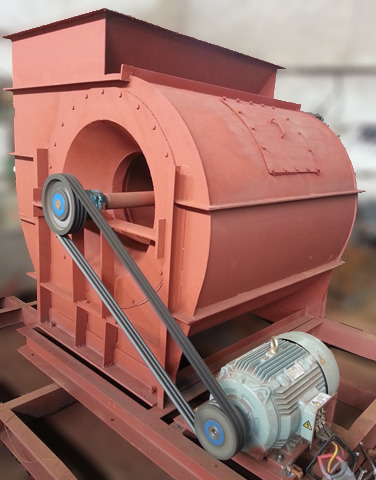

Centrifugal Blowers and Fans

Centrifugal fans or blowers are versatile ventilation devices that can provide high air pressure and flow, making them suitable for various ventilation needs in the ceramic industry. They can be used for:

- Exhausting dust and fumes: Generated during cutting, grinding, and polishing processes. Centrifugal fans can efficiently remove these contaminants, improving air quality and worker health.

- Providing supply air: Fresh air is crucial for maintaining a comfortable and healthy work environment. Centrifugal fans can bring in fresh air to compensate for exhausted air, preventing stagnation and stuffiness.

- Cooling equipment: Centrifugal fans can be used to cool down machinery and electrical components, preventing overheating and ensuring optimal performance.

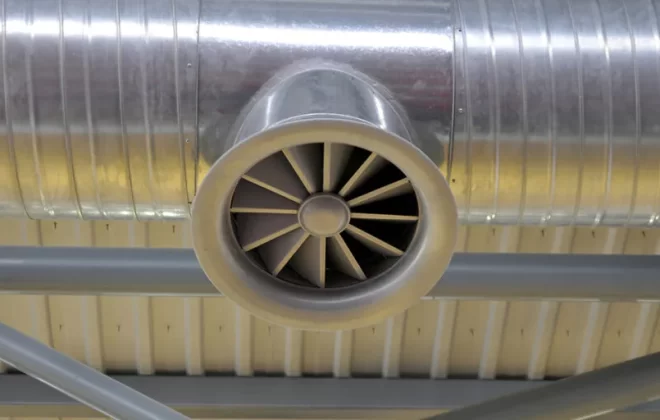

Exhaust Systems

These are comprehensive systems designed to capture and remove contaminants from the workspace. These systems extract harmful fumes produced during high-temperature processes like kiln firing, ensuring the air quality remains safe. They can be combined with centrifugal fans or blowers, and the crucial components of an exhaust system are:

- Exhaust Hoods: These are installed at various points in the manufacturing process to capture fumes and gases directly from the source.

- Ductwork: Ducts are used to transport captured fumes and gases from the exhaust hoods to the main exhaust system.

- Exhaust Fans: These fans create suction within the exhaust system, pulling fumes and gases through the ductwork and out of the manufacturing facility.

- Filtration Units: In some cases, exhaust systems may include filtration units such as scrubbers or particulate filters to remove contaminants from the air before they are released into the atmosphere.

Air Washer Systems

Air washer systems are devices used for air purification and climate control in indoor environments. These systems combine air filtration with water spray to clean and humidify the air. They are beneficial for:

- Controlling dust: Water spray effectively captures dust particles, providing cleaner air for workers.

- Humidity control: Maintaining optimal humidity levels is crucial for certain ceramic production processes and can also improve worker comfort.

- Odour control: Air washers can help remove unpleasant odours generated during some ceramic processes.

Wet Ventilation Systems

These systems use water to cool and clean the air. They are suitable for:

- Cooling workspaces: Particularly beneficial in hot and humid climates, wet ventilation systems can provide a more comfortable work environment.

- Dust control: Similar to air washer systems, wet ventilation systems can effectively capture dust particles.

Problem-Solving Capabilities:

- Improved air quality: All the mentioned products and systems contribute to better air quality by removing dust, fumes, and other contaminants, leading to a healthier and safer work environment for employees.

- Enhanced productivity: Improved air quality and thermal comfort can lead to increased worker productivity and reduced fatigue.

- Reduced maintenance: Efficient dust removal systems can minimize dust buildup on equipment, reducing maintenance costs and downtime.

- Odour control: Air washer and wet ventilation systems can help control unpleasant odours, creating a more pleasant work environment.

Now, as we have analyzed the solutions to the problems, you can choose the best equipment according to the requirements of your workspace. From dust control to temperature regulators, Symbiosis Blowerfab provides solutions to all the ventilation problems that arise in the ceramic industry’s operations.

To get reliable and high-quality ventilation solutions, feel free to contact the leading industrial blower and fan manufacturer in India. We also offer customized industrial fans for different industries according to their requirements.

Related Posts

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry