4 Important Centrifugal Fans & Their 5 Extraordinary Application

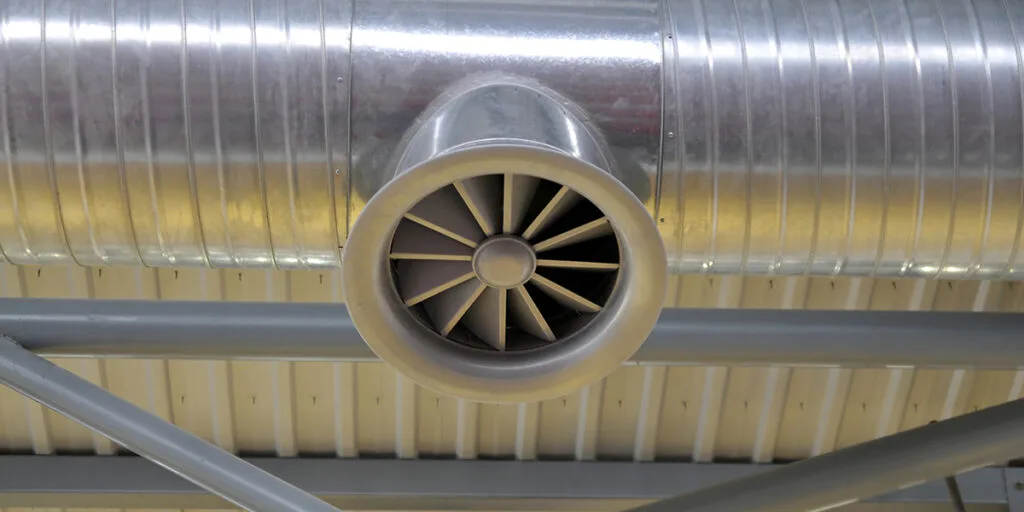

Centrifugal fans, also known as radial fans, are mechanical devices used to move air or gas in various industrial and commercial applications. They are designed to generate a high airflow volume with moderate pressure, making them ideal for use in Ventilation Systems, HVAC systems, and industrial processes requiring air movement.

Centrifugal fan come in various sizes, designs, and configurations, each suited to different applications. Each centrifugal fan type has its unique features, advantages, and applications, based on their design and the orientation of the blades.

Centrifugal Fans can be Classified into 4 Main Types

- Forward Curved Centrifugal Fans: Centrifugal fans with Curved Blades inclined forward are called forward-curved fans. They are perfect for use in low-pressure applications, including HVAC systems, air purifiers, and dust collectors, since they provide significant airflow at low pressures. They are suitable for usage in settings where noise is a concern because they are also relatively quiet.

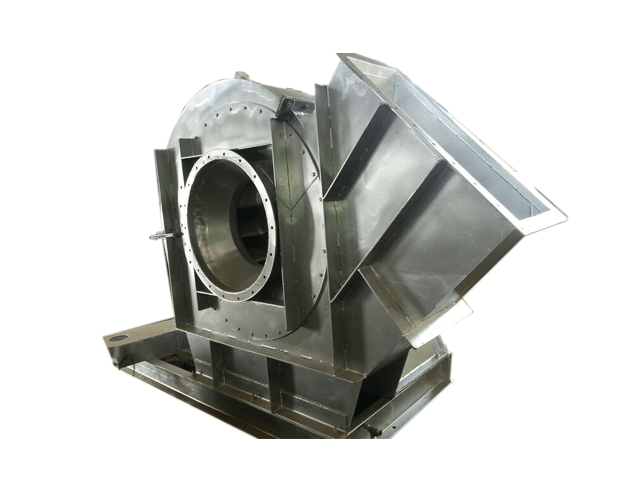

- Backward Curved Centrifugal Fans: Backward-curved centrifugal fan have blades curved backward, generating a higher pressure than forward-curved fans. They are efficient at moving air and suitable for high-pressure applications such as industrial ventilation systems, air conditioning, and refrigeration systems.

- Radial Centrifugal Fans: Radial centrifugal fan produce high-pressure airflow in a radial direction. They are frequently utilized in industrial settings, including pneumatic conveying, industrial exhaust systems, and material handling.

- Aerofoil Centrifugal Fans: Centrifugal fan that resemble aerofoils blades that resemble them, much like the aerofoils of an aircraft wing. They are effective at moving enormous amounts of air because they produce a high airflow volume at high pressures. They are frequently used in industrial exhaust systems, HVAC systems, and others.

How Centrifugal Fans Work:

Centrifugal fans convert mechanical energy from a motor into kinetic energy used to move air or gas. The motor rotates the impeller, consisting of blades that move air radially or axially. As the air moves through the impeller, it gains kinetic energy, converted into pressure as it is forced through a duct or outlet.

Applications for Centrifugal fans:

Centrifugal fan find various applications in various industries due to their ability to generate high-volume airflow with moderate to high pressure. Here are some of the most common applications of centrifugal fans:

- HVAC Systems: Centrifugal fans are widely used in heating, ventilation, and air conditioning HVAC systems to move air through ducts and distribute it throughout a building. They are also used in air handling units to regulate temperature and humidity levels.

- Industrial Ventilation: Centrifugal fans are used in Industrial Ventilation Systems to Exhaust Fumes, smoke, and other pollutants from manufacturing processes, warehouses, and workshops. They are also used to maintain a positive pressure in cleanrooms to prevent the entry of contaminants.

- Air Purification: Air purification systems use Centrifugal fan to remove dust, pollen, and other airborne particles. They are commonly found in air purifiers, air scrubbers, and dust collectors.

- Material Handling: Centrifugal fan are used in Material Handling systems to transport bulk materials such as grain, sand, and flour. They are also used in pneumatic conveying systems to move powdered and granular materials through pipelines.

- Power Generation: Centrifugal fan are used in power plants to provide cooling air to the condenser, which converts steam back into the water. They are also used in cooling towers to dissipate heat from the cooling water.

Wrapping up,

Centrifugal fans are crucial to many industrial applications, from HVAC systems to material handling and power generation. Choosing the Right Centrifugal Fan from Blowerfab for your application is essential to ensure optimal performance and efficiency.

By understanding the different types of centrifugal fans and their applications, you can select the right fan for your needs and achieve the desired results from the best Centrifugal Fan Manufacturer in India.

Related Posts

Recent Posts

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project