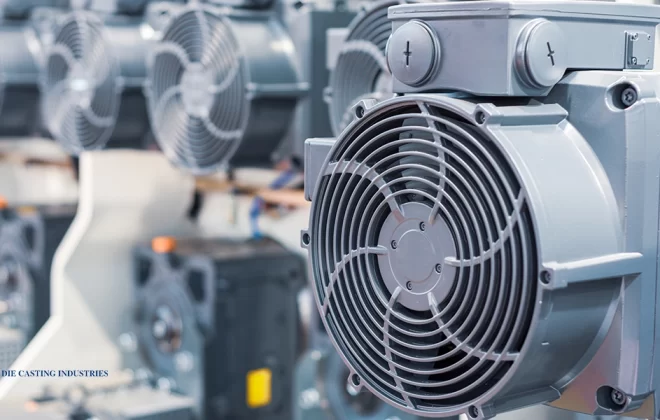

Industrial Blower Fans Used for Industrial Cooling Processes: An Overview of the 6 Application

Industrial cooling processes are essential to maintain optimal working conditions and protect equipment, machinery, and workers from overheating. This article will explore the different types of fans and blowers used for industrial cooling and their various applications. From ventilation and spot cooling to process cooling and air conditioning, Blowerfab will give you a comprehensive overview of how fans and blowers play a crucial role in the industrial cooling process. This blog post provides a better understanding of the key concepts and technologies used in industrial cooling. So, let’s dive in and explore the world of industrial blower fans.

Here’s an overview of the application of industrial blower fans in industrial cooling processes:

1. Ventilation:

Ventilation is a critical component of the industrial cooling process, as it helps to remove hot and contaminated air from the workspace and replace it with fresh, cool air. Industrial blower fans play a key role in circulating air and promoting air exchange.

The amount of air required for adequate ventilation can be substantial in large industrial spaces, such as factories and warehouses. Industrial blower fans are designed to handle large volumes of air, making them ideal for these applications. They can pull hot and contaminated air out of the workspace and replace it with fresh, cool air. This helps to maintain air quality and prevent the buildup of harmful pollutants and chemicals, which can pose a health risk to workers.

2. Spot Cooling:

Spot cooling refers to the process of cooling specific areas within an industrial space, such as workstations, machinery, and equipment, to prevent overheating and extend their lifespan. Industrial blower fans play a crucial role in circulating air and removing heat.

In industrial settings, certain areas or equipment can generate a significant amount of heat, causing temperatures to rise and putting stress on the equipment. Over time, this can lead to equipment failure and downtime, reducing efficiency and productivity.

Using industrial blower fans for spot cooling, facilities managers can target specific areas or equipment generating heat and remove that heat by circulating cool air over the surface. This helps to prevent overheating and extend the lifespan of the equipment.

3. Process Cooling:

Industrial cooling Processes refers to removing heat generated during industrial processes, such as welding, drying, and curing, to maintain optimal operating conditions and protect equipment and workers from overheating. Industrial blower fans play a crucial role in this process by circulating cool air and removing heat.

For example, in welding processes, the heat generated from the welding process can cause temperatures to rise and put stress on the equipment and workers. By using industrial blower fans to cool the process, facilities managers can remove heat from the welding area and maintain a comfortable working environment for workers. This

4. Evaporative Cooling:

Evaporative cooling is a process that uses water to cool hot, dry air. It works by evaporating water into the air, which removes heat and creates a cooling effect. Industrial blower fans can be used with evaporative coolers to provide an efficient and cost-effective cooling solution.

In this system, an industrial blower fan draws hot, dry air through a moistened pad or media. Water evaporates as the air passes through the moistened material, removing heat and creating a cooling effect. The industrial blower fan circulates the cooled air into the workspace.

This cooling system is particularly effective in hot, dry climates where the air is dry, and air conditioning could be more effective. Using evaporative cooling with industrial blower fans provides a cost-effective and energy-efficient solution, as it uses less energy than traditional air conditioning systems.

5. Air conditioning

Air conditioning refers to cooling and dehumidifying the air in a space. Blower fans can circulate air in air conditioning systems, helping distribute cooled air evenly throughout the space.

A refrigerant-based system in air conditioning generates cool air and is then distributed throughout the space by a blower fan. The blower fan circulates the cool air, ensuring that it is evenly distributed throughout the space, creating a comfortable and controlled environment.

By using blower fans in air conditioning systems, facilities managers can improve the efficiency of the cooling process and reduce energy consumption. Blower fans can also distribute cool air to hard-to-reach areas, such as high or hard-to-reach spaces, improving the space’s overall comfort and air quality.

The type of industrial blower fan used in an industrial cooling process will depend on several factors, including the size of the space, the cooled process, and the desired level of cooling. By understanding the different applications of industrial blower fans in industrial cooling, facilities managers and engineers can make informed decisions about the best cooling solutions for their operations.

Conclusion

In conclusion, industrial blower fans play a crucial role in industrial cooling processes. From ventilation to air conditioning, spot cooling to industrial cooling processes , and even heat recovery, industrial blower fans provide a versatile and efficient solution for maintaining optimal operating conditions in industrial spaces. By understanding the different applications and selecting the right type of fan, facilities managers and engineers can ensure the proper cooling of their operations and protect their equipment, machinery, and workers from overheating. According to Science Direct, Best practices in industrial ventilation

Connect with us!

Tags In

Related Posts

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry