4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry

The automotive industry, a combination of innovation and precision, relies on numerous intricate processes. Central to its efficiency is the management of air—an often overlooked yet vital aspect. Let’s delve into the complexities of the automotive sector and explore how industrial blowers and fans play a pivotal role in combating challenges and driving operational efficiency.

Ventilation Problems Faced by Automotive Industry

The automotive industry, with its diverse manufacturing processes, faces multifaceted challenges. From heat generation during welding and engine production to air quality concerns in painting booths, the need for a comprehensive ventilation system is evident. Achieving the delicate balance between precision and efficiency becomes paramount.

Industrial Blowers and Fans– The Solution

The automotive sector faces many difficult situations during operations, which can be resolved by using effective and efficient industrial blowers and fans in accordance with the specifications. Let’s find out how these air ventilation systems can combat various challenges in the automotive industry processes.

1). Combating Heat with Precision Cooling

The manufacturing processes within the automotive sector, particularly welding and engine production, generate substantial heat. Uncontrolled heat can hamper machinery performance and compromise the hygiene and efficiency of the workforce.

Centrifugal blowers act as an ingenious solution to avoid excessive and unwanted heat. Centrifugal blowers provide precise and efficient cooling for machinery, ensuring optimal performance and creating a comfortable working environment. Precision cooling enhances equipment longevity and safeguards the well-being of workers.

2). Clearing the Air in Paint Booths

Painting and finishing processes demand stringent air quality standards. Fumes, dust, and airborne particles can compromise the quality of finishes and pose health risks to workers.

To overcome this, industrial exhaust fans emerge as key players in maintaining high air quality standards. These exhaust fans efficiently remove pollutants, ensuring a clean and controlled environment for impeccable finishes. The reliability of these exhaust fans is integral to the seamless functioning of automotive paint booths.

3). Optimizing Ventilation for Overall Efficiency

Proper ventilation is crucial for overall operational efficiency in an automotive facility. Stagnant air pockets can disrupt processes and compromise the well-being of the workforce.

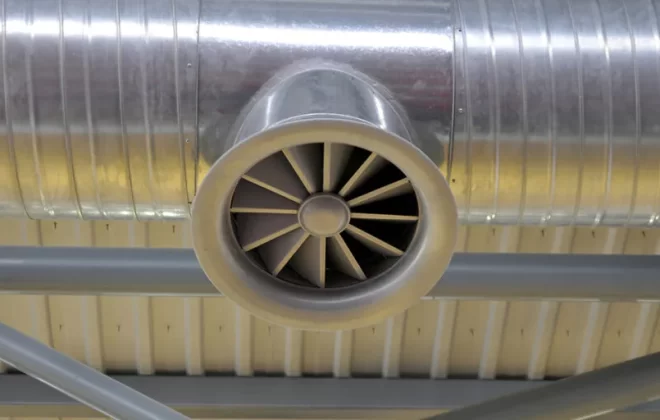

The use of axial flow fans, a versatile solution for efficient air movement, can prevent this situation. Axial flow fans prevent stagnant air pockets, maintaining a comfortable working environment. These fans provide optimal ventilation throughout the facility, ensuring every corner benefits from consistent airflow.

4). Enhancing Air Quality with Advanced Solutions

In areas with sensitive electronic components, addressing pollutants and contaminants is paramount. Advanced air quality solutions become essential in maintaining a clean and healthy workspace.

Air washers and wet ventilation systems stand out as advanced solutions. These systems efficiently address pollutants, providing an additional layer of protection in areas with sensitive electronic components. The combination of precision and sophistication in these solutions ensures an environment conducive to human health and machinery performance.

In the intricate phase of automotive manufacturing, the role of industrial blowers and fans is transformative. By facilitating proper ventilation systems, industrial blowers and fans will enhance productivity, product quality, and worker safety in the automotive manufacturing processes.

Symbiosis Blowerfab – The Leading Industrial Blower and fan Manufacturer

With a wide range of products available, including centrifugal fans, axial flow fans, and exhaust fans, Symbiosis Blowerfab provides efficient and reliable ventilation solutions for various industries. The precision cooling, air quality maintenance, and efficient ventilation provided by these solutions contribute to the overall efficiency of automotive operations.

Symbiosis Blowerfab emerges as a reliable partner in driving efficiency within the automotive industry. Our experienced engineers and technicians work closely with clients to design customized systems that meet their specific requirements. As the automotive industry continues to evolve, the transformative impact of Symbiosis Blowerfab’s ventilation solutions becomes increasingly evident, solidifying their position as pioneers in industrial blower and fan technology.

Contact Symbiosis Blowerfab to explore how their solutions can revolutionize your automotive operations. Elevate your efficiency, enhance air management, and embrace the future of automotive manufacturing with Symbiosis Blowerfab, India’s leading industrial fan manufacturer.

Tags In

Related Posts

Recent Posts

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants