5 Considerations for the Right Selection of a High-Temperature Industrial Fan

Some industrial processes involve temperature applications, which require high-temperature industrial fans that can resist airflow temperatures as high as 2000 degrees Fahrenheit. ‘High-temperature industrial fan’ means a fan capable of withstanding extremely high heat.

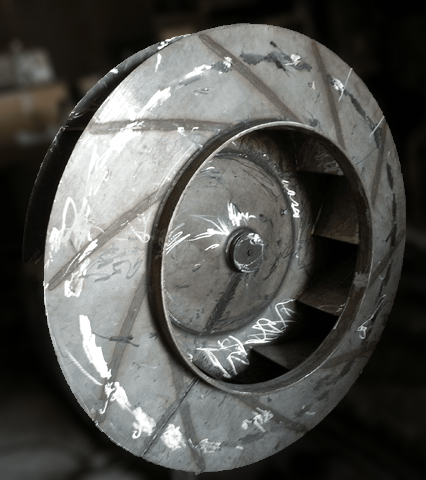

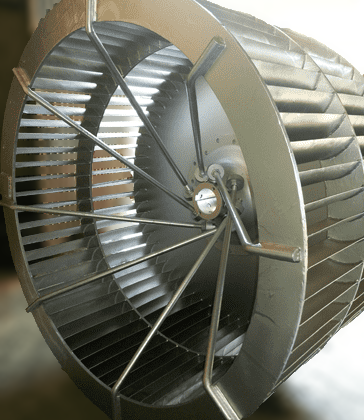

Therefore a high-temperature industrial fan is built with additional special construction features, to meet the demands of specific industrial operations. It is generally made up of thicker material gauges, larger shaft assemblies, bearings with increased bearing life, and corrosive-resistant material.

While there is a wide range of fan suppliers offering high temp industrial fans; it is important to understand that reliable fans must be designed and built specifically for the challenges of various high-temperature applications.

With a view to helping simplify your selection process; we’ve listed 5 considerations that go into the right section and construction of high-temperature industrial fans.

- Application:

- The specific application will be a determining factor for the type of fan to use in any industrial process. (I.e. Axial, Centrifugal, Mixed flow or turbo, Backward Inclined Fans, Forward Curved Fans, and Radial Flat Blade Fans).

- Most high-temperature applications have unique requirements that can make fan specifications complicated. The key is to identify the system information a fan manufacturer needs to design and supply a product optimized for the application. Moreover, to specify a fan for maximum service life, it is important to understand the factors influencing fan design and construction.

- The amount of time a fan can be expected to be exposed to high-temperature air can vary, depending on a fan’s projected use. Thus, a fan can be rated for a short, defined duration or it can be rated for continuous operation. For example – Main ventilation fans and jet fans used in a roadway or transit tunnel aim to evacuate air in the event of a fire. So these fans are rated for a short duration, normally 1 or 2 hr. Other fans, such as those for petrochemical processing and those for forced circulation or recirculation of air or gas in furnaces, ovens, kilns, and dryers, are rated for continuous operation. So accordingly the selection of high-temp. The industrial fan should be done.

- A high-temperature industrial fan is characterized by its application, construction, material types, and material gauges.

2. Communication:

The key to ensuring proper selection and construction of a high-temperature industrial fan is effective communication between the consulting engineer or end-user and the manufacturer.

- The person most familiar with the requirements of a high-temperature industrial fan should handle communication. The fan manufacturer should be furnished with details related to fan specifications, challenges experienced with past installations and the concerns regarding the current fan selection.

- In order to ensure right selection of a highly reliable and efficient fan; it is essential to consider the requirements for the end-use process, location, installation, schedule and future operation.

3. Experience:

Most high-temperature industrial fan applications have unique requirements that can make fan selection complicated. Hence, only an experienced & expert industrial fan supplier with specific high-temperature industrial fan knowledge and capability can produce a high-temperature industrial fan, which will perform for your high-temperature application.

- So it is important to check the fan vendor’s track records as well as his ability to trouble shoot high temperature fan issues before selecting a high-temp industrial fan.

4. Engineering Support:

Rather than choosing a standard, one-size-fits-all/ready-made high temperature industrial fan, choose a high-temperature fans supplier; who can offer you the engineering support to build a custom high-temperature industrial fan that meets your unique application challenges.

- Even in the optimum running conditions, a high temperature industrial fan may ultimately need service or repair due to mechanical wear over time. Plus Preventive maintenance (PM) of the fan and its components is also important throughout the life-cycle of a high temperature industrial fan. So consult with your fan supplier and discuss the terms about the maintenance of high temp industrial fan during the fan selection.

5. Specifications:

To make the right selection, one must clearly identify the specifications – General Information as well as In-Depth Requirements, if necessary.

General information includes-

- Application

- Type of gas being moved

- Number of systems

- Fans per system

- Type of fan required: axial, centrifugal, mixed flow, or turbo

- Fan arrangement and control

- Expectations regarding the equipment life

- Ancillary items to be supplied by the fan manufacturer

Besides that the end-user must derive the following conditions the fan or blower will be subjected to:

1. The required airflow: It is rated in cubic feet of air per minute (CFM) or in metric equivalent, it is rated in cubic meters per hour (M³HR).

3. The static pressure through the system: Rated in static pressure water gauge (SPWG) or in metric equivalent, it is rated in Pascal’s (Pa). SPWG or Pa is the resistance to flow, or friction, caused by the air moving through the system.

4. The ambient air temperature outside the fan

5. The airflow conditions through the fan

- Maximum operating temperature?

- Clean or dirty air?

6. The altitude the fan will be operating at.

Conclusion: To put it simply, the high temp industrial fan selection will be based on the type of fan that is best suited by performance, design, and features that best meet those conditions.

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry