5 importance of Industrial blowers and fan in the Aerospace Industry

Are you aware of the game-changing Importance that industrial blowers and fans bring to the aerospace industry?

Discover how these powerful airflow solutions can revolutionize your aerospace operations and enhance safety, efficiency, and productivity.

Are you ready to harness the true potential of industrial blowers and fans in the aerospace industry?

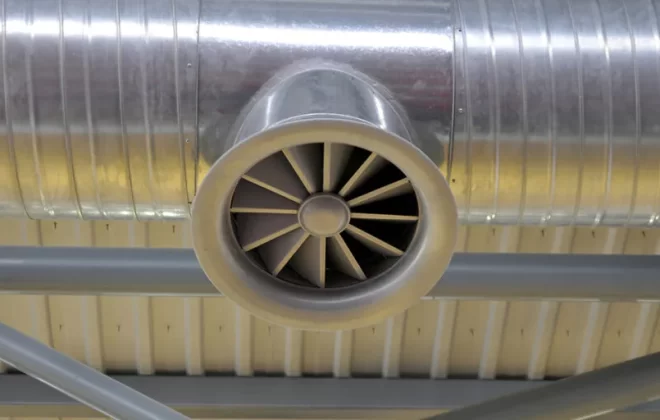

Industrial blowers and fans serve as indispensable components within the aerospace industry, making a substantial impact on maintaining ideal working conditions, prioritizing safety, and optimizing efficiency. Harnessing their impressive airflow capabilities, these equipment deliver a multitude of advantages and fulfill vital functions that are essential to the aerospace industry.

In the aerospace industry, which encompasses aircraft manufacturing, maintenance and repair facilities, and testing facilities, the presence of industrial blowers and fans is indispensable. These critical components ensure optimal airflow, temperature control, elimination of airborne contaminants, and the facilitation of efficient processes.

Aerospace professionals gain a valuable understanding of how these equipment contribute to seamless operations and create a favorable work environment by recognizing their significance.

Industrial blowers and fans have significant importance in the aerospace industry, and the following are five crucial roles they play.

- Ventilation and Air Quality Control: In aerospace facilities, industrial fans and blowers have significant utilization to guarantee adequate ventilation and uphold ideal air quality. These systems play a crucial role in eliminating impurities, regulating temperature and humidity, and promoting fresh air circulation.

As a result, they contribute to the creation of a work environment that is healthier and more comfortable for personnel. - Cooling and Heat Dissipation: A wide range of equipment and machinery operate, generating substantial heat. Industrial blowers and fans are utilized to deliver cooling and dissipate heat for engines, electronic components, avionics systems, and other equipment sensitive to high temperatures.

By enabling effective airflow and cooling, these fans actively prevent overheating, extend the lifespan of essential components, and ensure consistent and dependable operation even in extreme conditions. - Smoke and Fume Extraction: During emergencies like fires or incidents involving hazardous materials, industrial blowers and fans become crucial come extraction of smoke and fumes.

These systems are specifically designed to eliminate smoke, toxic gases, and other airborne pollutants, thereby enhancing visibility, assisting in evacuation procedures, and ensuring the safety of individuals.

In aerospace facilities, the implementation of effective smoke and fume extraction systems holds immense importance in reducing harm, safeguarding valuable assets, and prioritizing the well-being of personnel. - Airflow Control in Wind Tunnels: Wind tunnels are extensively used in the aerospace industry for aerodynamic testing and research. industrial blowers and fans play a vital role by delivering precise and controlled airflow. Their function is to replicate diverse airspeeds and conditions, enabling engineers to evaluate the performance and characteristics of aircraft, spacecraft, or different components exposed to varying aerodynamic forces.

- Pressurization Systems: In the aerospace industry, industrial blowers and fans find application in cabin pressurization for commercial aircraft. Their purpose is to uphold a secure and pleasant environment for both passengers and crew members when flying at high altitudes.

These systems achieve this by providing a constant supply of fresh air and regulating the pressure within the cabin. This ensures the maintenance of sufficient oxygen levels, prevents the accumulation of condensation, and reduces the impact of altitude on the human body.

Adequate pressurization is of utmost importance for ensuring passenger comfort, well-being, and overall safety during flights.

Summing Up,

The importance of industrial blowers and fans in the aerospace industry cannot be overstated. These powerful airflow solutions are crucial components that contribute to the smooth functioning of aerospace facilities and operations.

From ensuring optimal airflow and temperature control to eliminating airborne contaminants and enhancing safety, these systems provide a wide range of benefits that are essential to the aerospace industry. The five roles they play, all demonstrate the game-changing impact that industrial blowers and fans bring to the aerospace sector.

By harnessing their full potential, aerospace professionals can enhance safety, efficiency, and productivity, making these solutions invaluable in the industry.

If you are involved in the aerospace industry and seeking top-quality industrial blowers and fans, your search ends here! Get in touch with UDCI, Blowerfab, the premier industrial blower fan manufacturer in India.

Feel free to reach out to us, the leading industrial fan manufacturer in Gujarat, India, for further assistance and inquiries.

Tags In

Related Posts

Recent Posts

- How Industrial Fans Transform Ventilation Systems in Smart Factories

- How Centrifugal Blowers Help Optimize HVAC Systems in Large Facilities

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency