What is Indoor Factory Air Pollution? – Sources, Effects and Control

Breathe in, breathe out – it’s a natural and essential process we do without thinking. But have you ever stopped to consider the quality of the air you’re breathing in a factory or industrial setting? Poor indoor air quality/Indoor factory air pollution is a common issue in many factories, and it can have serious consequences for both workers’ health and productivity.

In this blog post, we’ll dive into the sources and effects of Indoor factory air pollution and what it is. Explore some effective methods for controlling it.

What is Indoor Factory Air Pollution?

Indoor factory air pollution pertains to the existence of noxious substances and pollutants in the air within factory or industrial environments. These pollutants are emitted during diverse industrial operations and can cause harmful impacts on human health and the environment.

Factories and industrial facilities frequently participate in manufacturing, processing, and production activities that utilize machinery, chemicals, and energy sources. As a result, a diverse array of pollutants is emitted into the air during these processes, contributing to substandard indoor air quality.

The types of pollutants found in indoor factory air can vary depending on the specific industry and processes involved. Common contaminants include volatile organic compounds (VOCs), particulate matter (PM), sulfur dioxide (SO2), nitrogen oxides (NOx), carbon monoxide (CO), and various chemical fumes and gases. Exposure to indoor factory air pollution can have significant health consequences for workers and nearby communities.

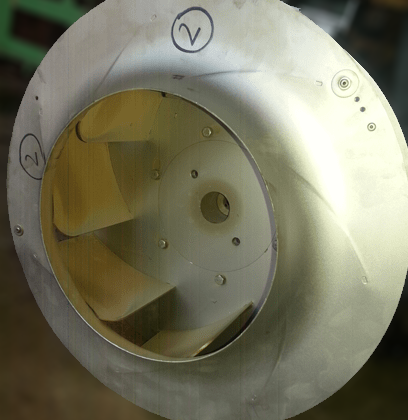

Moreover, addressing Indoor factory air pollution is crucial for protecting both human health and the environment. By promoting cleaner and more sustainable practices within industrial blowers and fans, it is possible to minimize the adverse effects of indoor factory air pollution and create healthier working environments for employees.

Sources of Indoor factory air pollution:

Indoor factory air pollution originates from diverse sources that are inherent to industrial settings. Among the primary sources are:

- Industrial Processes: The emission of pollutants into the air arises from manufacturing, processing, and production activities that encompass the use of machinery, energy sources, and chemicals. These emissions stem from processes such as combustion, chemical reactions, and the handling of hazardous substances.

- Particulate Matter (PM): Processes like grinding, cutting, or material handling generate fine particles that are dispersed in the air, resulting in respiratory issues and decreased air quality.

- Volatile Organic Compounds (VOCs): Solvents, paints, adhesives, and cleaning agents commonly employed in industrial processes frequently contain volatile organic compounds (VOCs). These compounds have the ability to evaporate, leading to indoor air pollution and presenting potential health hazards.

- Chemical Fumes and Gases: Industries engaged in chemical-related processes, such as metal refining or chemical manufacturing, release harmful fumes and gases including sulfur dioxide (SO2), nitrogen oxides (NOx), and carbon monoxide (CO), which pose detrimental effects on human health and the environment.

Effects of Indoor Factory Air Pollution

Indoor factory air pollution has wide-ranging consequences, impacting human health and the environment in several ways:

- Health Consequences: Employees exposed to Indoor factory air pollution may encounter immediate effects such as eye, nose, and throat irritation, along with headaches and respiratory ailments. Extended exposure can result in the development of chronic respiratory conditions, cardiovascular disorders, and even specific forms of cancer.

- Environmental degradation: Environmental degradation occurs as airborne pollutants contribute to the creation of smog, acid rain, and the exacerbation of climate change. Moreover, when these pollutants eventually settle, they contaminate soil and water sources, thereby posing significant risks to ecosystems.

Control Measures for Indoor Factory Air Pollution

Mitigating indoor factory air pollution necessitates the implementation of proactive measures and control strategies. Here are some effective approaches:

- Ventilation Systems: Ventilation systems play a crucial role in promoting a healthier work environment by facilitating the efficient removal of contaminants and ensuring the constant supply of fresh air.

- Pollution Control Technologies: The utilization of state-of-the-art air pollution control technologies, including electrostatic precipitators, scrubbers, and catalytic converters, plays a crucial role in minimizing emissions and enhancing the quality of indoor air.

- Cleaner Production Methods: Embracing cleaner and more sustainable production approaches, such as utilizing environmentally friendly materials and optimizing energy consumption, aids in reducing pollution generation at its origin.

- Regulatory Compliance: Compliance with stringent air quality standards established by governments and regulatory bodies is of utmost importance for factories. It ensures that necessary measures are implemented to effectively control and mitigate indoor air pollution.

In Conclusion,

Indoor factory air pollution presents notable difficulties for human health and the environment. Gaining knowledge about its sources, effects, and control measures is crucial in striving for safer and healthier industrial environments. Installing ventilation systems, employing pollution control technologies, and utilizing air pollution control equipment all contribute to mitigating the impact of indoor factory air pollution.

For the finest air pollution control equipment in Surat, get in touch with Symbiosis Blowerfab. As one of the leading providers of air pollution control equipment in Gujarat, India, we offer top-notch products and services. Contact us today to learn more about pricing options and benefit from exceptional sales assistance.

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry