How do Air Blowers work?

Air Blowers can be categorized into two types:

Industrial Centrifugal Fans and Axial Fans. They are used evidently in the industrial and commercial setup. It is widely used to move the gas aeration around the building continuously. These machineries are capable of displacing large amounts of air from air blowers.

Thus, having great importance in heavy-duty industries like Cement industries, Textile industries, Pulp & paper industries, Glass industries, and Power Plant boilers.

The workings of the Blower Fans depend on the type of fans and in what industries they are used. Both, the Centrifugal Fans as well as Axial Fans have different parts and have varied processing’s up to a certain extent.

Industrial Centrifugal Fans:

- INLET AND OUTLET DUCTS – The inlet duct is attached to the front of the air blower. This duct controls the air circulation moving into the blower fan. Whereas, the outlet duct attached at the end imposes certain resistance to the air leaving out of the duct from air blowers.

- FAN CASING – The fan casing houses the main fanning gears. Here the centrifugal fan force is generated making it the most important part of the airflow system. The casing is made of hard materials so as to ensure protectivity.

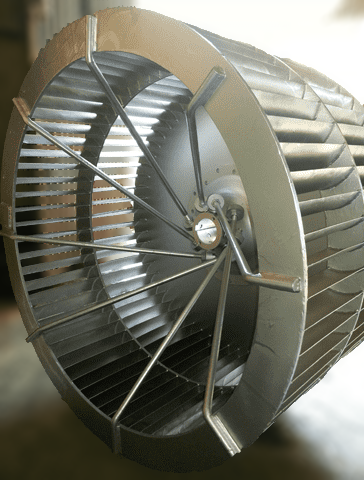

- FAN BLADES – The blades are responsible for carrying the airflow through the blower fans. They come in different curved directions depending on which the functionality differs. The different aerodynamic designs available in the market are: Backward type Aerofoil, Backward Curved Blower, Backward Inclined Type, and Radial Bladed Type.

- IMPELLERS – It is a device mounted on a hub and comprises of different fan blades. Depending on the shape of the fan, these impellers help with the force to be given to the circulating air.

- MOTOR – Here, the incoming air from air blower is put under pressure by applying electrical energy.

- ROTOR SHAFT – The shaft connects the blades with the motor. The rotor shaft mechanism determines the speed of the fans.

The air enters from the inlets —> The inflow of air from air blower is directed towards the fan casing –> The air generated is circulated towards the fan base –> the force created when the fan rotates throws the air away from the impellers towards the outlet –> With a certain resistance, airflow releases out.

Such Industrial Blower Fans allow for a buildup of high air pressure as a result of the centrifugal process. This makes them an ideal choice for releasing out massive air pressures in heavy industries. For example in cement industries, where continuous pollutants are released as the end product, air blowers can be used for cleaning the air.

Axial Centrifugal Fans:

In Axial Fans, when the air enters inwards, the impellers rotate on their own axis. They draw the air into the fan system and discharge the inside air in the same direction but outward.

Similar to the Centrifugal Fans, Axial Fans also have a fan mechanism. The Axial Fans include:

1. INLET & OUTLET DUCT – The duct provides the entry and exit of the air. There is an inlet cone at the entrance of the fan which allows the air to enter into the fan mechanism. The outlet cone, as it suggests provides the way for air to leave outwards.

2. PROPELLER MECHANISM – Here lies the fan’s impeller, wheel, and rotor. The rotary device drives the incoming airflow towards the exit.

The Axial Fan blades cause an aerodynamic lift to build up. So, when the air passes through the inlet, pressure is created from behind the mechanism. The act of rotary movements brings the air more inwards towards the outlet.

Such fans require low pressure but a high flow rate. That is why Axial Fans work best where the large volumetric flow has to be generated. They are generally used in confined spaces where air cooling is required. For example, in ventilation systems as exhaust fans, or in computers for keeping the CPU from overheating.

The workings of both the fans are quite simple and easy to understand. Being a certified Industrial Blower Fans manufacturer in India, Usha Die Casting Industries, our technical experts will be happy to assist you right from installation to explaining the mechanism. Contact Blowerfab to know about the price range and also to know more about a centrifugal air blowers.

Recent Posts

- How Industrial Fans Transform Ventilation Systems in Smart Factories

- How Centrifugal Blowers Help Optimize HVAC Systems in Large Facilities

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency