Axial vs. Centrifugal Industrial Fans: The Differences Between 2 fans That You Must Know for Proper Application

Industrial fans are widely used in commercial and industrial settings. They are used in several industrial setups like Textiles, Glass, Telecommunications, Mining, Cement, Agriculture, etc. as a cooling and product transfer machine. Several important and popular uses of industrial fans include ventilation, commercial & industrial cooling, heat exhaust, and air duct exhaust.

Depending on their application and uses, Industrial Fans are divided in two types- Centrifugal Fans and Axial Fans. Though their applications are similar in most ways, they highly differ in their shapes, sizes, order of application, functions, designs, etc. As a Trusted and experienced industrial fans Manufacturer in Gujarat, we have curated our blog post to thoroughly understand the difference between centrifugal fans and axial fans.

What are Centrifugal Blower Fans?

Centrifugal fans are also called as centrifugal blower fans. These fans generate centrifugal forces powered by rotating disks with blades at a right angle. Centrifugal blowers employ a revolving impeller to drive air centrifugally outwardly, then directly away from the blade tips. These fans can generate high pressures, making them suited for severe operating circumstances such as high-temperature systems, damp or unclean air streams, and material handling.

Centrifugal Blowers are commonly used in boiler fans, furnace combustion blowers, rolling mill dust collectors, bag filters, suction blowers, and exhaust blowers. The primary function of centrifugal blower is to generate enough pressure to suck in, circulate, and release new air. It is also in charge of producing high pressure and forceful airflow from a small amount of air/gas.

To know about the Effect of blade number on the performance of centrifugal fan with the reference of SCIENCE DIRECT

What are Axial Fans?

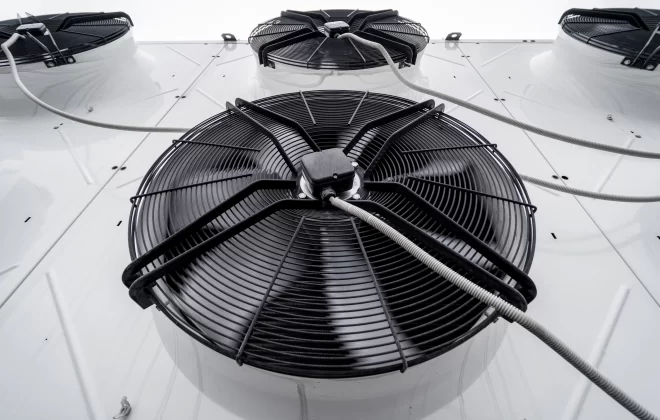

Axial Industrial Flow Fans use axial forces to move air or gas by spinning a central hub with blades that extend radially from its outer diameter. The fluid is propelled in a straight line parallel to the fan wheel’s shaft, or axis of rotation. Axial flow fans are highly efficient and are frequently utilized in rooftop ventilation applications.

Axial blowers are used for simple extraction or cooling applications that need very little system resistance, such as transferring air from one huge room to another or condenser cooling in refrigeration. Typically used for exhausting contaminated air or delivering fresh air, unidirectional or reversible air-flow applications, and exhausting applications with small particulate size, such as dust streams, smoke, and steam.

Basic Difference Between Axial Industrial fans & Centrifugal Industrial fans

| Differentiating Factors | Centrifugal Industrial Fans | Axial Industrial Fans |

| Construction | Blades of centrifugal fans are positioned axially on the rotor. Because the blades are perpendicular to the rotor axis, air is propelled out in a radial direction on rotation. Due to centrifugal motion, the air is circulated and radially transmitted out. | The fan blades are attached to the rotor hub’s circumference. The blades revolve to blow air in a direction parallel to the rotor’s axis. An electric motor drives the rotor blade assembly. For protection against dust and debris, the entire assembly of motor, rotor, and blades is encased inside a casing. |

| Applications | Used in industrial ventilation. Essential for air conveyor systems. Used in air duct exhaust gas operations. Used as secondary fluid transfer equipment in air turbines. | Used in cooling towers. Used in air-cooled condenser assemblies. Used as heat exchangers. Used in HVAC and packaging cooling tower operations. |

| Volume & Pressure | High volume / low pressure | High pressure / low volume |

| Airflow | Airflow parallel to axis | Airflow perpendicular to axis |

| Speed | Higher operating speed than centrifugal | Lower operating speed than axial |

| Design | Compact designs | Better for specific directed cooling |

| Power Usage | Lower power usage than centrifugal | Typically uses more power than axial |

| Noise | Less audible noise than centrifugal | More audible noise than axial |

| Durability | Typically less expensive than centrifugal | Durable and resistant to harsh environments |

In Conclusion, the above mentioned are the basic differences between an Axial Industrial Fan & Centrifugal Industrial Fan. Before buying any industrial fan from an industrial fans dealer, it is advisable to look for major differences.

Need assistance with industrial fans selection? Connect with our experienced industrial fan manufacturer in Gujarat.

Related Posts

Recent Posts

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project