Uses of industrial fans in 3 main Industrial Plants

Did you know industries that do not use industrial fans often encounter significant difficulties in ensuring safe and efficient operations?

Industrial fans come in various sizes and types, from small portable fans to massive industrial-sized units that can handle a significant amount of air movement. They are a critical component in many industrial processes and facilities, including manufacturing plants, power plants, mines, etc.

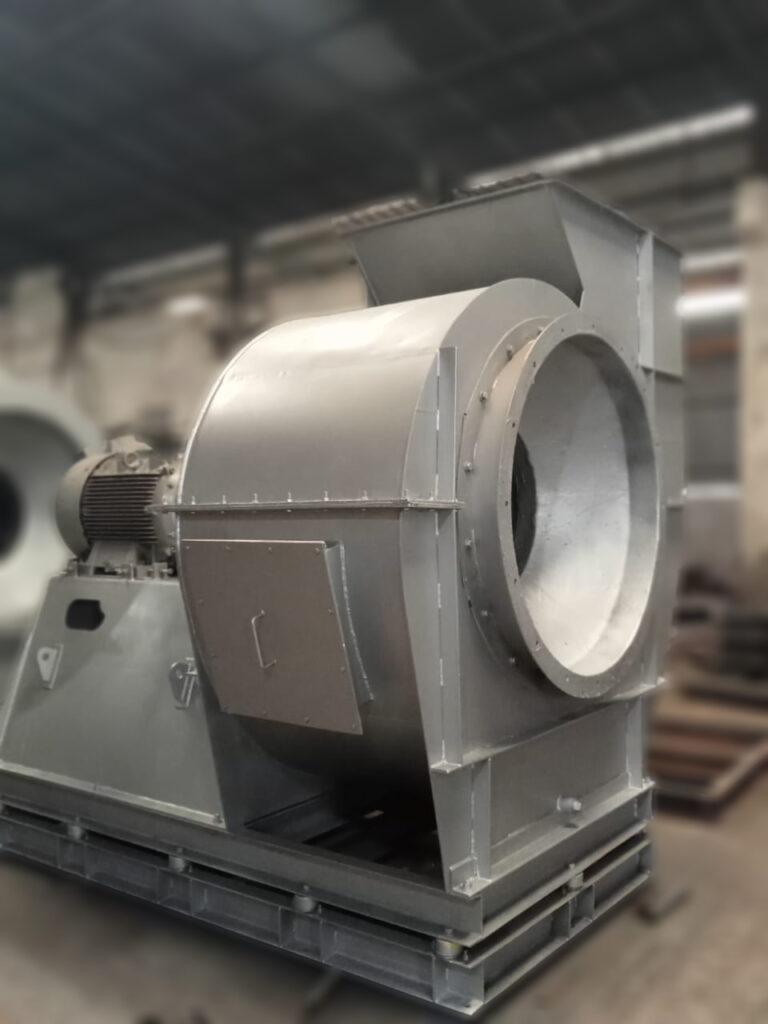

Centrifugal fans are commonly used for ventilation, cooling, drying, dust collection, and providing combustion air.

They are the vital components in various industrial plants as they have a wide range of applications. Industries like cement industry, agriculture industry, glass and pulp industry are large-scale production facilities where industrial fans are densely utilised.

Discover the Top 3 Industrial Plants that Rely on Industrial Fans

Cement industry

High-temperature processes used in the production of cement lead to exhaust fumes with dangerous contaminants. These gases are drawn from the kiln using industrial fans, which then route them to the air pollution control devices. Industrial Blower fans also assist in supplying air for fuel combustion during the cement manufacturing process.

Read, Industrial blower Fan Solutions For Cement Industry Applications.

Cement industry requires industrial fans for several critical applications,

1. Combustion air: High-temperature fuel combustion is required for the cement making process. To ensure efficient combustion, industrial Blower fans are employed to feed the combustion air to the kiln burners.

2. Exhaust from the raw mill: Before being fed into the kiln, the raw materials needed to make cement must be ground into a fine powder. Industrial fans are required to remove the heat and dust that the grinding operation produces.

3. Coal mill exhaust: The cement industry frequently uses coal as a fuel. Industrial fans are used to extract the coal mill’s exhaust gases, which may contain hazardous chemicals and particulates.

4. Material handling: The production of cement requires the movement of significant amounts of materials, including gypsum, clay, and limestone. These materials are moved from one stage of the manufacturing process to the next using industrial fans.

Agricultural industry

Industrial Blower fans are used in crop drying. In order to avoid mould growth and maintain the quality of the harvested material, crops must be dried properly. The drying process can be speed up and the possibility of spoilage decreased by using industrial fans to blow air over the crops.

The agricultural industry requires industrial fans for several critical applications,

1. Ventilation in livestock barns: Keeping the animals’ and employees’ air healthy and lowering the danger of illness require proper ventilation. Industrial blower fans are used to move the air in the barns and extract the stagnant air, assisting in avoiding the accumulation of dangerous gases and particulates.

2. Climate control in greenhouses: For plants to flourish in the best conditions possible, greenhouses need to be in regulated surroundings. Utilising industrial blower fans to control temperature, humidity, and airflow can aid to encourage plant development and boost crop yields.

3. Controlling humidity and temperature in storage facilities: Controlled conditions are necessary for agricultural items like fruits and vegetables to maintain freshness and prevent spoiling. In order to improve the overall quality of the stored goods, industrial fans can be employed to control the temperature and humidity levels in storage facilities.

4. Dust and particle removal in processing facilities: Dust and other airborne contaminants can harm equipment and pose a risk to the health of workers. Dust and other airborne particles can be collected and removed from processing areas by using industrial fans to create negative pressure.

Glass and pulp industry

Industrial fans are employed in the glass sector to supply cooling air for the glass manufacturing furnaces, which run at extremely high temperatures. The cooling air ensures the manufacturing of high-quality glass products while assisting in the prevention of equipment damage. In the regions where molten glass is moulded into finished items, industrial fans are also employed to regulate temperature and provide ventilation.

Glass and pulp industry requires industrial fans for several critical applications,

1. Temperature control and furnace cooling: Extremely hot environments like those found in pulp digesters and glass production furnaces necessitate cooling and temperature management to protect equipment and guarantee the creation of high-quality goods. Industrial fans are used to deliver cooling air and regulate the temperature in these places.

2. Combustion air supply: Industrial fans provide air supply for combustion in the production process, maintaining consistent process conditions and improving overall efficiency.

3. Efficiency of the process: Industrial fans are essential for preserving the general effectiveness of the pulp and glass manufacturing processes and ensuring the manufacture of high-quality paper and glass.

In Conclusion,

Usha Die Casting Industries offers Industrial Blower fans that are essential elements for many industrial plants, necessitating the production of high-quality goods and effective production operations.

Employing the right quality fan can fetch you remarkable outcomes. Selecting a reputable industrial fan manufacturer in India who offers superior quality fans, top-notch services, and competitive pricing is crucial in the realm of industrial fans.

Contact Symbiosis Blowerfab – the leading industrial fan manufacturer in Gujarat and Discover more about our exceptional industrial fans.

Related Posts

Recent Posts

- Solving Ventilation Challenges in the Ceramic Industry with Symbiosis Blowerfab

- Commercial Kitchen Ventilation Systems: A Complete Guide for Restaurants

- 6 Ways Air Washer Systems Enhance Efficiency in Industrial Processes

- 6 Ways to Ensure Adequate Air Ventilation in Battery Manufacturing Industry

- 4 Ways Industrial Blowers and Fans Enhance Efficiency in Automotive Industry