What to Check to Ensure Proper Installation of Your Industrial Blowers?

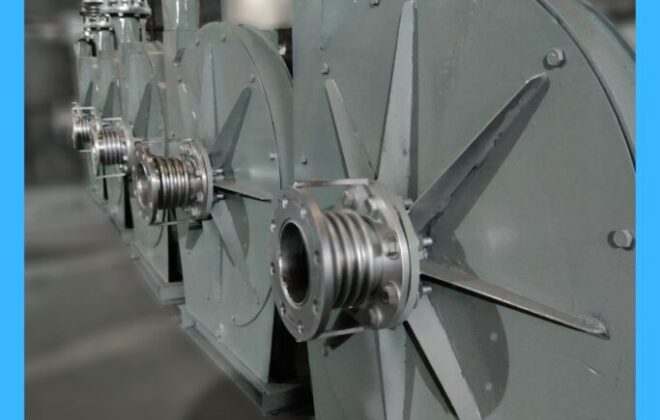

Various types of industrial Blowers are vital pieces of equipment in any industrial setup. Industrial Blowers are used in operations and applications where the flow of gas or air is necessary such as conveying systems, ventilation, cooling, aspiration, and exhaust systems. As industrial blowers serve as important means of creating safe working conditions by enhancing airflow, it is recommended to install them with expert advice.

Improper installation may result in electric shock, injuries from contact with moving parts, and other potential hazards. However, it is advisable to seek installation assistance from the Best Centrifugal Fan Manufacturer.

Here’s the list of fundamental things you need to check while installing the industrial blowers.

Planning:

Proper planning is essential while installing an industrial blowers. To ensure the right planning,

- Review all design and installation documents including requirements for fire and explosion protection, minimum hood and duct velocities.

- Review operating conditions and verify locations for test ports, dampers, balance valves and fittings.

- Review the Ventilation System design to ensure that all access doors are closed and that duct interferences have been checked and eliminated.

- Review the operating requirements of the blower, motor and drive system.

- Location for installing a fan is complete and ready to accept blower upon arrival.

- Cranes, tools and equipment needed for installation are available.

- Check if properly trained personnel are available and prepared to handle the blower.

- Prepare an installation and start-up evaluation procedure and share it with all the plant personnel. Such procedures must be followed to ensure that, the system is properly balanced before the start-up.

Receiving:

Be sure to thoroughly inspect your shipment while receiving your blower for shortage or damage. Inspect the blower for dents, scrapes, bent shafts, broken parts, etc. Compare paperwork with items being received for proper items and quantity. Verify all parts are present, properly assembled, and in working order.

Handling:

It is important to lift/carry the blower as per the instructions. The components of the blower need to be shifted with the utmost care, as the minute damage in any part may disturb the working condition of the whole device.

Placement:

- Place the blowers on a level surface. Entrance to the blower room must be large enough to accommodate both the Blower package and the equipment used to move it. The mass of the base (where the blower will be installed) should be capable of withstanding normal vibration.

- Do not position the blower so close to the wall that the cooling air flow is obstructed. The blower should be properly grounded.

- While it is advisable to install the blowers indoors, if it is required to be installed outdoors; it must be protected from adverse weather conditions.

- Properly plan and ventilate the blower room to ensure the optimum equipment performance and longevity. Exhaust ventilation fans can be fitted to provide the blower room with adequate ventilation.

- Protecting blowers from building up dust/dirt on it extend its life.

- The blower must be isolated from any near-by vibration.

Electrical Supply:

Before installing the blower, make sure that your electrical service voltage matches the voltage on the blower nameplate. The blower must be internally wired for proper voltage. Get all the wiring and electrical connection work done by a trained electrician, in accordance with prescribed standards.

Start-Up:

Precautions must be taken before starting up the fan, even if it has passed the test run at the factory. Ensure that all the safety accessories are installed before starting the fan. Never exceed the maximum RPM stated for the blower, accounting for speed de-rating factors due to temperature and materials of construction.

Consider checking

- All the electrical connections and keep a check on the voltage too.

- Alignment of blower’s components.

- All drive and inlet/outlet guards are installed properly.

- If the bearings have been lubricated. Verify that coupling, if supplied, is lubricated.

- Installation of an industrial blower must be done by a fan professional. Hence finding an Experienced Manufacturer is very essential to get a suitable Air Cleaning System and UDCI remains one of the most reliable Industrial blower manufacturers in India. At UDCI, we offer expertise solution in commissioning of air pollution controlling equipment.

Do you want to Know more about Industrial Blowers?

Visit for industry knowledge and updates. Blowerfab

Tags In

Recent Posts

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project