Industrial Fans and Blower for Pulp and Paper Industry

Fans and Blowers play a vital role in every industry. They help to keep the environment as well as the workers safe and thus remain at the core of the smooth running of a factory. Hence a variety of fans are installed specifically to the industry process.

Paper & Pulp is one such industry, wherein a variety of high or low-pressure fans and blowers are required throughout the production process for supplying and exhausting air. Various applications such as drying to bleaching produce chemical-laden airstreams and high temperatures require fans to provide stable airflow and circulation through these systems.

Spacious facilities with hot, steamy air and lots of fine paper particulate matter in the air portray pulp and paper manufacturing environments. Extreme heat and corrosive chemicals make it a demanding application for the fans used in numerous processes in the pulp & paper manufacturing facility. Air containing dust or substances in suspension requires specific, highly efficient abatement processes; ventilation is required for a safe and clean working environment.

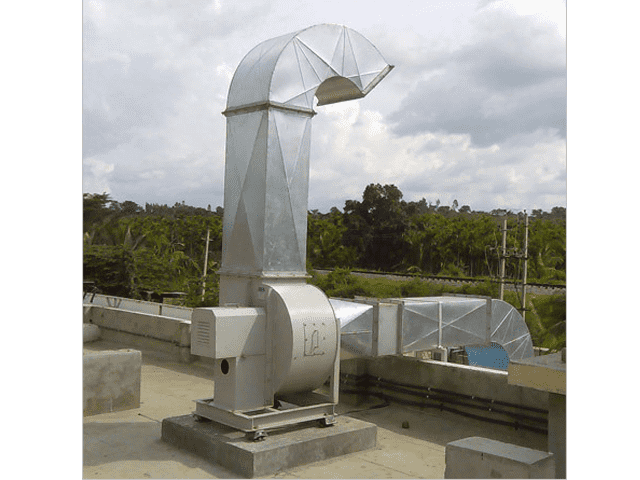

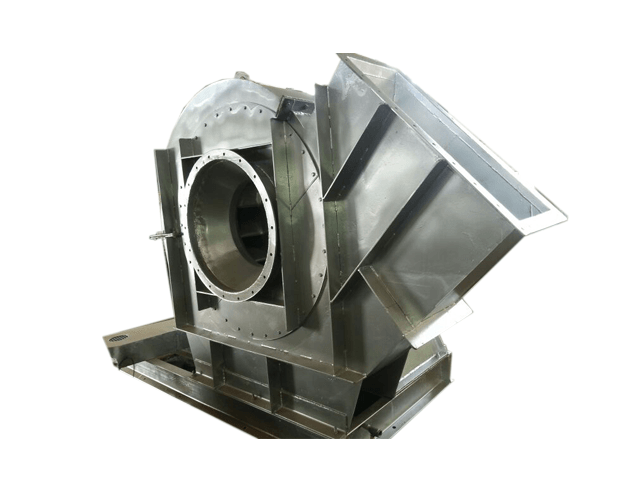

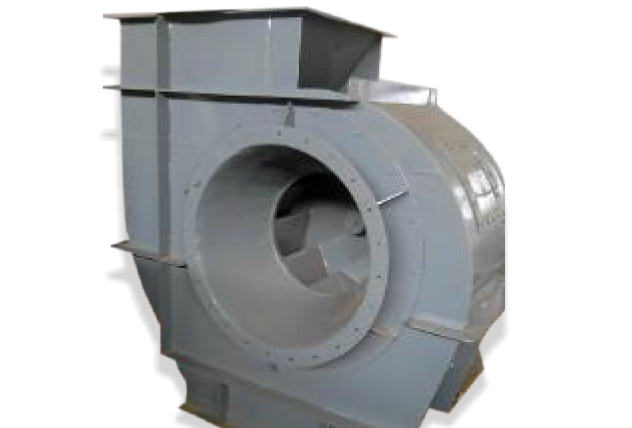

Centrifugal Fans and Blower are preferred at the paper and paperboard production facility for energy recovery, safeguarding the environment, and waste disposal.

These fans are used with typical applications such as –

- Heat recovery and exchangers

- Cooling, air feeding, abatement for energy production systems

- Waste incinerators

- Drying of wastes

The paper machines require a high-pressure dryer and heater box fan equipment. Paper machine dryer fans are usually coated with corrosion-resistant paint or have stainless-steel construction. Environmental systems such as particle, odor, and fume removal use Industrial Fans and Blowers designed specifically for the paper & pulp industry. Pulp applications are more akin to a chemical process and hot & chemical-laden airstreams are common, necessitating fans constructed from corrosion-resistant materials such as polypropylene, stainless steel, or other high-tech alloys.

The paper manufacturing industry utilizes fans for Power Boilers, recovery boilers, lime kilns, dissolving tanks, and dryers. These applications, which are integral to the production process, are often very corrosive. Therefore reliability and durability of fans and blowers for such applications are vital for continuous operation.

Industrial fans and blowers required by the Specific process systems as well as related applications from the beginning of the process to the finished product in the Pulp & Paper industry are mentioned below

Drying and Heat Recovery:

Drying is one of the key parts of the paper production process and the hood plays an important role. The paper and Pulp industry generally use fans to dry material before it is sent for further process. Industrial Fans are used to dry the paper, which continuously runs on the rolls at a certain speed which usually depends on the type of paper to be produced.

Hi-tech manufacturing and processing for paper and cardboard require high-temperature resistance industrial fans (dedusting fans, exhaust fans, shredder fans) to fully satisfy the needs of this industrial sector. It calls for specific applications and systems with a particular focus on energy saving. In Paper production processing, the heat recovery systems work with the high temperature of the steam. Air heat exchangers are often used for this process.

De-dusting and Ventilation:

The Paper machine production process produces fine dust which pollutes the air. A clean and safe working environment is very important for operators in a pulp & paper manufacturing setup. The operative area (machine hall) requires optimal conditions and paper, paperboard, and tissue machines require proper conditions to work with optimum capacity without deposits of dust. Industrial fans and blowers applied infiltration devices contribute to removing the dust and provide the correct ventilation required to control temperature and humidity levels too. They also ensure the protection of the machinery, plants facilities, and building from corrosion, damage, and worsening thanks to a balanced climate.

Shredding Fans:

Shredders are the right solution to remove edge stripes after the cut during the continuous paper production process and convey the trims to the pulper or collected and pressed. Different construction features for many kinds of paper and paperboards make it a very interesting solution for the recycling process.

Chemical Applications:

In this category of the paper production process, industrial fans and blowers may be required to be produced in a special configuration and with the most suitable corrosion-resistant materials.

Explosion Proof:

Industrial Fans and Blowers may be mandatory because of zone classification (Hazardous Area). In the production plants for paper production or converting some activities may require filtration for dust that may be ignited. Some processes require solvent or chemical solutions.

Paper Machine Exhaust:

Airflow is critical to paper machine processes. Exhausting the gas from a Yankee Hood or other paper machines requires a high level of detail and engineering. This process may require Forced Draft, Induced Draft, Primary Air, Flue Gas Recirculation, Regenerative Thermal Oxidizers, or Process fans as per the plant application.

We leverage our vast experience and expertise to offer you the industrial fans and blowers that deliver the highest performance & efficiency, to withstand tough pulp and paper industry applications.

Get in Touch with us to know more about Industrial fan in detail.

Related Posts

Recent Posts

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency

- Hubergroup Elevates Production Capabilities Using SYMBIOSIS Blowerfab’s Stainless Steel Blowers

- SYMBIOSIS Blowerfab Supplies Tailored Blower Solutions to Antony Lara’s Waste Treatment Project