Top 5 Industrial Processes where Centrifugal Fans are Used

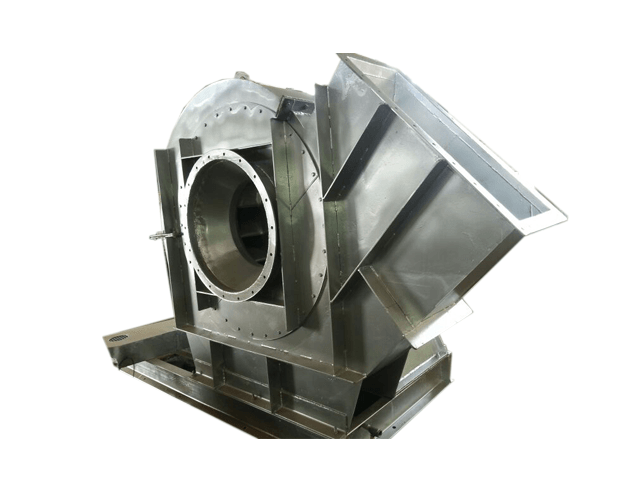

Industrial Fans or Blower Fans/Centrifugal Fans are an efficient and cost-effective way of generating continuous and intermittent airflow to industrial processes.

Such fans are effectively used for most industrial processes like cooling, ventilation, aeration, drying, and conveying materials. Industrial fans are specifically designed to operate at high and low temperatures, with corrosive gases, acidic fumes, and built-in air pressure.

Industrial Fans ensure proper ventilation to the industry employees and the customers. Industries like steel plants, chemical industry, paper and pulp industry, textile industry, food industry, and glass industry can utilize it to regulate hot air generated from heavy machinery.

We are an experienced Centrifugal Fan manufacturer in India. We have listed down the industrial processes where Industrial blower fans can be utilized.

1). Industrial Cooling:

Industrial fans often termed industrial cooling fans are used to displace air or gas from one point to another. The primary function of the fan is to drive in the cold air and blow hot air out of the industrial environment.

- In cement manufacturing industries, a large number of cooling fans are used. It blows cold air to the cooler and cools the clinker from 1500oC to 100oC.

- Similarly, in glass manufacturing industries, cooling fans are required. They are used to cool down the temperature of the oven walls to cool the glass material.

Common industrial cooling fans used for cooling are airfoil, backward inclined fans, or high-pressure radial fans.

However, the hot air exhaust depends on the design and construction of specific fans. These cooling fans have a large diameter which helps them produce large volumes of air as required by the industrial process.

2). Air Re – Circulation:

In heavy industries heat and energy production is massive. A stable and consistent airflow is needed to maintain proper fuel combustion.

- For instance, Centrifugal Fans in industrial boilers allow fresh air to blow into the system. This process maintains the oxygen levels required for ignition.

- In Steel manufacturing industries, Industrial Circulation Fans are used for circulating cool air into the ovens. The circulation maintains a homogeneous temperature inside the oven.

- In power plant boilers, Forced Draft Fans (FD) supply the air necessary for fuel combustion. The process involves pushing air through the combustion air supply system and into the furnace.

3). Re- Dusting:

In every industry, centrifugal fans have wide usage of dust collection. There are many variations of dust collectors to remove nuisance such as process dust. The fans used are either forced draft fans or induced draft fans through the system.

The re-dusting process requires centrifugal fans to work on the depression-type system and pressure-type system applications.

And, in depression-type system application, backward inclined or airfoil centrifugal fans are used. The fan is mounted on the tip of the cyclone or within the filtering system to remove airborne particles.

Backward Curved Blower Fans and Backward Inclined Centrifugal Fans designs are the most common technology options for clean air while Industrial Exhausters are ideal for handling contaminants.

4). Air Drying:

Industrial Forced or Induced Draft Fans are needed in industrial processes to control the temperature and moisture content. Hot air is forced through the fans to circulate the air needed for removing excessive moisture.

- In Paper Industry, these fans are used for drying sheets of paper. It may occur either by passing the material through a heated oven or exhausting the air of the paper pulp.

- Similarly, in Food Processing Industries, Centrifugal Dryer fans are required. The Fan removes the moisture content from the food before it is sent to packaging.

Also, in cement industries, dryer fans are used for drying the clinker in a kiln system.

Centrifugal Fans used for industrial drying are airfoil, backward curved, backward inclined, and radial fans.

5). Conveying Materials:

Industrial centrifugal fans are used for handling and conveying materials. Small and light materials like sand, plastic pallets, sawdust, and wood chips can be easily handled by average Centrifugal Fans. But for heavy industrial materials such as steel and other alloys, abrasion-resistant centrifugal fans are required.

Common centrifugal fans required for conveying materials are high-pressure Radial Fans or Industry Exhauster Fans.

We are expertized Industrial Centrifugal fans manufacturer in India. Thus, we can assist you with the right Centrifugal Fan appropriate for certain industrial processes.

Related Posts

Recent Posts

- How Industrial Fans Transform Ventilation Systems in Smart Factories

- How Centrifugal Blowers Help Optimize HVAC Systems in Large Facilities

- How Industrial Blowers Improve Air Quality and Safety in Factories

- How to Improve Cement Plant Performance with High-Efficiency Blowers and Fans

- SYMBIOSIS Blowerfab Delivers State-of-the-Art RC Fans to ArcelorMittal Nippon Steel India, Enhancing Industrial Efficiency